Understanding M12 Electrical Connectors

An M12 connector is a type of electrical connector commonly used in industrial settings for connecting sensors, actuators, and other devices. It's known for its high-speed signal transmission and power-feeding.

ATTEND provides both m12 socket (female connector) and m12 plug (male connector) formats with various coding styles and standard compliances, such as the IEC61076-2-109 with X coding and ISO 11801 for Ethernet.

In terms of performance, you can expect M12 connectors to offer high tolerance in harsh environments, optimal electrical stability, and secure connection mechanisms.

M12’s Various Coding and Pin Assignments

Here’s an overview of our M12 connector series coding and specifications:

| Series | Key Feature | Pin Count | Connector Types | Current & Voltage Rating |

|---|---|---|---|---|

| 216A | M12 A code | 2, 3, 4, 5, 6, 8, 12 |

|

|

| 216D | M12 D code | 4 |

| 4A/250V |

| 216X | M12 X code | 8 |

| 0.5A/50VAC or 60VDC |

A-Coded M12 Connectors

A-coded M12 connectors are versatile options for general-purpose industrial connectivity. They are commonly used to connect sensors, actuators, and other devices requiring both signal and power transmission.

D-Coded M12 Connectors

D-coded M12 connectors are specifically designed for industrial Ethernet applications. They provide reliable data transmission for network connectivity in automation systems and other industrial environments.

X-Coded M12 Connectors

For high-speed data transmission in demanding industrial environments, X-coded M12 connectors are the ideal solution. They support Gigabit Ethernet and beyond, enabling real-time communication for video monitoring and high-precision control applications.

If you are unsure about which configurations to choose for your m12 sockets or m12 plugs, you may reach out to our experts for inquiries. We will help you find the best solutions for your specific application.

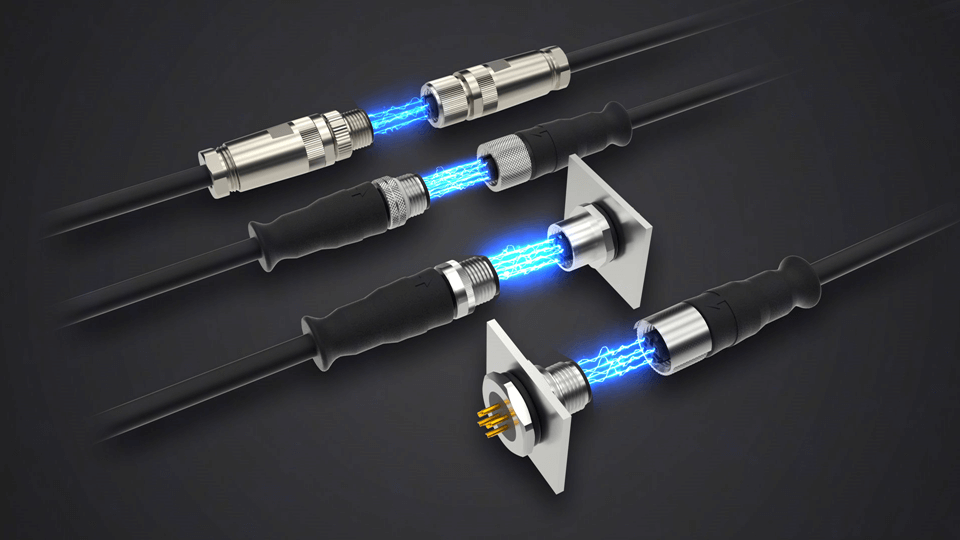

M12 Connection Options

At ATTEND, we offer diverse solutions so that you can seamlessly integrate the M12 circular connectors into your existing infrastructure while maintaining installation efficiency. Available options include:

- M12 Overmolded Cable Connectors: These M12 connectors come with pre-assembled cables so they can be used straight away. They also have a sealed layer around the cables, providing protection against moisture, dust, vibration, and fluctuating temperatures in harsh environments.

- M12 Field-Installable Connectors: Designed for on-site customization, these connectors can be soldered or crimped with simple tools, offering flexibility for cable length and other features. Still, users must select the right cable size and diameters to ensure compatibility with the M12 connector’s specifications.

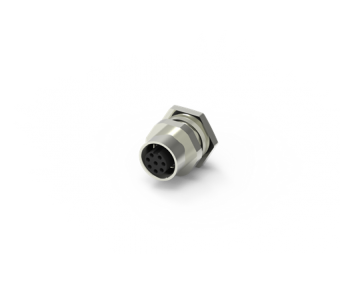

- M12 Bulkhead Connectors: Also known as panel mount connectors, they can be directly mounted on the front or rear of a bulkhead using threads, allowing for quick and flexible installation. They can also be soldered onto the components for a more robust connection.

- M12 PCB Connectors: These connectors are specifically designed for mounting on printed circuit boards (PCBs) with soldering or through-hole methods. This eliminates the need for additional mounting hardware, streamlining the installation process while allowing for a more compact design.

- M12 SMD Connectors: These Surface Mount Device (SMD) connectors are tailored for automated assembly processes using SMT equipment, such as solder paste printers, pick-and-place machines, and reflow ovens. This equipment will apply solder paste directly to the PCB pad before placing the M12 connectors in the designated area. The reflow oven will then heat the solder to secure the bond. This option reduces labor costs while ensuring precise and efficient mounting on PCBs.

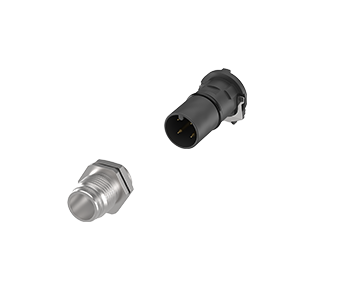

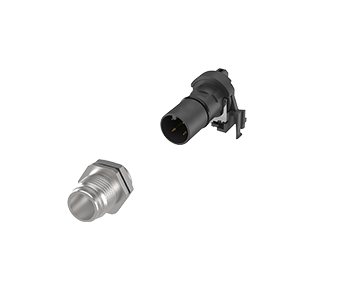

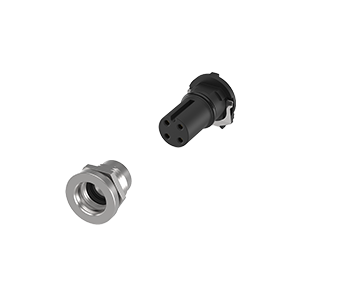

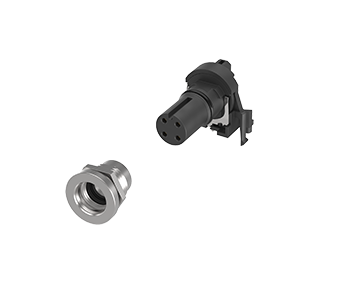

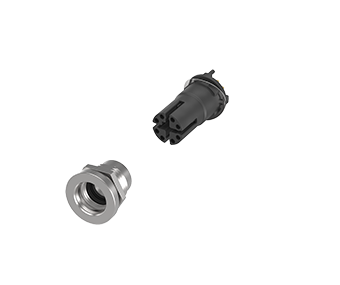

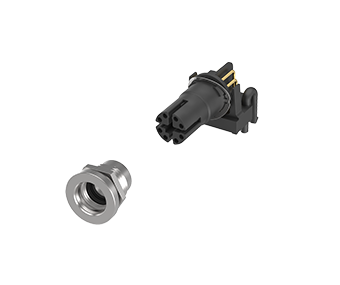

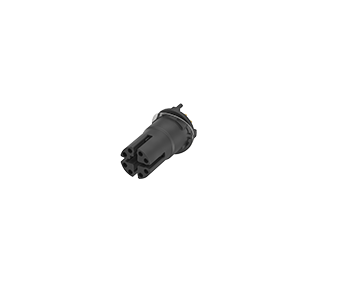

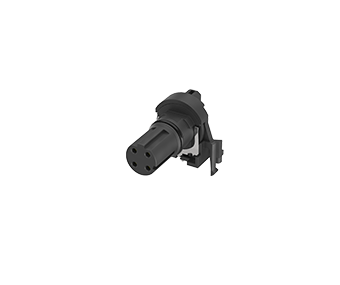

- M12 Two-Piece Connectors: These connectors feature a modular design that separates the contact insert from the housing. Available in threaded and push-pull housings with front or rear mounting options, two-piece M12 connectors allow easy adaptation to diverse PCB layouts using vertical or right-angle inserts. The design also simplifies maintenance, reduces inventory complexity, and enhances assembly efficiency, making it ideal for compact, high-reliability applications from industrial automation to robotics, transportation, and medical equipment.

M12 Circular Connector Advantages

ATTEND’s M12 circular connectors offer secure and stable transmissions, even in harsh environments.

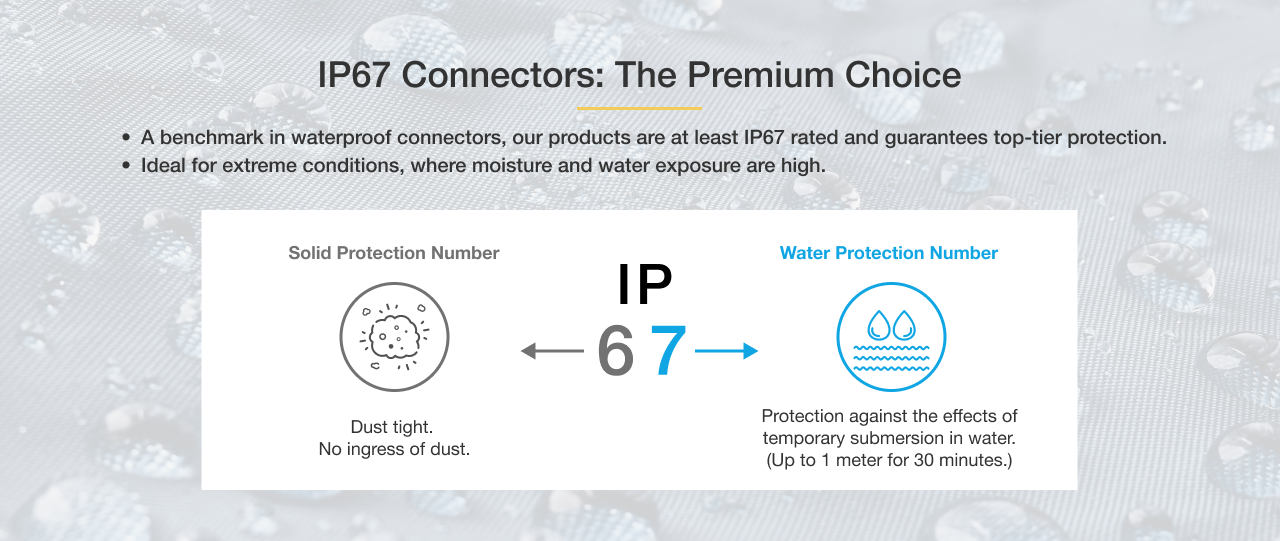

Harsh Environment Tolerance

- Waterproof Level IP67:

Guarantees protection against dust and temporary immersion in water, making it ideal for outdoor telecommunications and marine electronics.

- Operating Temperature -40°C to +85°C:

Ensures consistent performance in extreme temperatures, suitable for harsh climates like automotive systems and outdoor equipment.

Electrical Stability

- Current Rating Range:

0.5A ~ 20A

- Voltage Rating Range:

50V ~ 250V

Current and voltage ratings specify the maximum electrical load a connector can safely handle without compromising performance. An optimal power rating also reduces contact resistance to enable efficient current flow, lowering the risk of breakdowns or overheating in demanding applications.

With a wide current and voltage rating range, ATTEND’s M12 circular connectors can accommodate various applications, from low-power sensors to high-current power distribution.

Screw Locking and Push-Pull Mating

Additionally, ATTEND offers push-pull M12 connector options. This enables quick, tool-free mating to reduce operation time. The push-pull receptacles can even mate with threaded plugs while supporting both board-to-cable and cable-to-cable configurations, ensuring flexibility for applications that require frequent mating cycles. Despite this simplified operation, push-pull M12 connectors still provide robust mechanical retention and stable electrical performance in tough environments, along with a compact design to save space.

Why ATTEND M12 Connectors?

.png)

.png)

.png)

Success Stories

ATTEND’s M12 solutions continue to support efficiency, durability, and performance — helping manufacturers across various industries bring innovative, reliable products to market faster and with greater confidence.

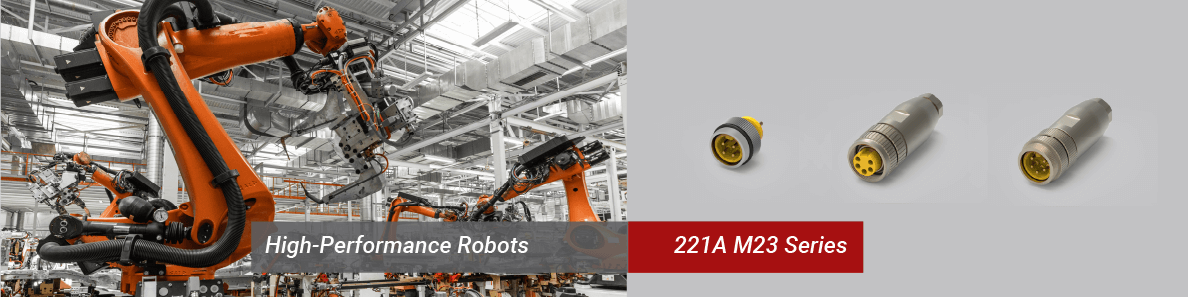

For instance, a client with high-performance robots found it challenging to find connectors that could withstand harsh environments while providing reliable data and power transmission. ATTEND’s M12 Series offered the perfect solution with its rugged design, environmental sealing, and versatile mounting options.

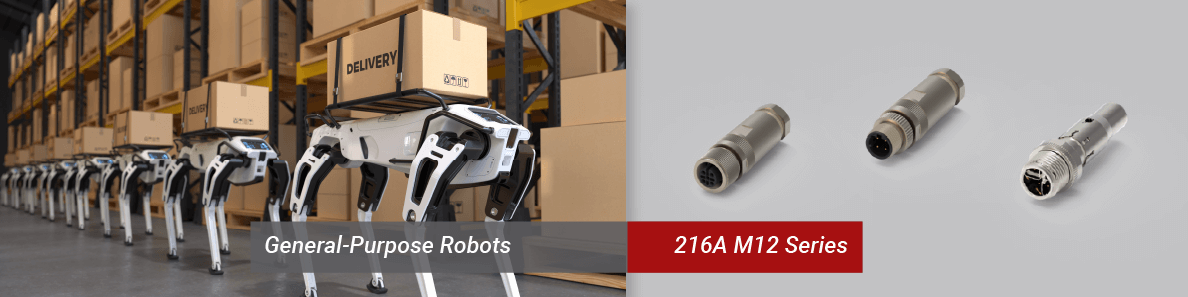

Furthermore, a robotics manufacturer integrated ATTEND’s M12 connectors into their general-purpose robots for material handling systems, significantly reducing maintenance downtime thanks to the connectors’ vibration resistance and secure screw-locking mechanism.

For compact robots and drones, where space and weight are limited, ATTEND’s M12 connectors provide a balance of robust performance and compact design, offering dependable signal and power connections without adding unnecessary bulk.

.png)

How to Assemble Our Field-Installable M12 Connectors

Our field-installed M12 electrical connectors are some of the most popular selections. While they offer flexibility, the assembly requires precision to ensure connection reliability. Here is a quick guide to help you understand the process:

-

Prepare the Cable: Slide the connector components — including the coupling nut, grommet, gripper, etc — over the cable.

-

Strip the Cable: Trim back the cable jacket by approximately 30 mm to expose the shielding. Then, carefully fold the shielding back over the jacket and secure it with electrical tape.

-

Strip the Insulation: Remove any foil or plastic covering the conductors and strip back the insulation of each wire by about 5 mm.

-

Connect the Wires: Attach the individual wires to the designated pins on the connector hub before soldering them in place. Most wires follow a number-coded or color-coded system, so you can match the wire placement accordingly to ensure correct alignment.

-

Fit the Components Together: Slide the connector hub into the housing and make sure the shielding is evenly distributed around the circumference. Trim excess shielding if necessary and fasten the pressing screw until it is hand-tight.

-

Secure the Connector: Screw on the coupling nut firmly to complete the installation. Inspect to ensure no stray shield wires fall back into the connector to prevent connection interference.

Ask Our Expert: Jaime Coreano | VP of Sales, North America

With more than 20 years of experience in the semiconductor and electronic components industry, Jaime Coreano is a trusted professional in the field of connectors, pogo pins, power supplies, LEDs, memory products, and more. His extensive knowledge of market trends and technical expertise has enabled him to support clients across diverse industries, including networking, industrial machinery, medical devices, computing, and military aviation.

Whether you have questions about M12 connectors or need guidance on selecting the right components for your application, Jaime is here to provide tailored solutions and expert advice to meet your unique needs.

Browse All of ATTEND’s M12 Electrical Connectors Below

Our versatility and commitment to quality ensure you get the best in class. Feel free to Contact Us to discover how M12 connectors from ATTEND can revolutionize your setups!

216A-XXFO1

216A-XXFO1 M12 A-Code Plug, XX Pin, Push-Pull, Female, G/F, Overmold

INQURY 216A-XXMO1

216A-XXMO1 M12 A-Code Plug, XX Pin, Push-Pull, Male, G/F, Overmold

INQURY 216X-08MO1

216X-08MO1 M12 X-Code Plug, Push-Pull, Male, Overmold, 10u"

INQURY M12-8R00-2427004

M12-8R00-2427004 M12 A-Code 8Pin Female to Open Cable, L=2M

INQURY M12-8P00-2427004

M12-8P00-2427004 M12 A-Code 8Pin Male to Open Cable, L=2M

INQURY M12-4R00-2427004

M12-4R00-2427004 M12 A-Code 4Pin Female to Open Cable, L=2M

INQURY M12-4P00-2427004

M12-4P00-2427004 M12 A-Code 4Pin Male to Open Cable, L=2M

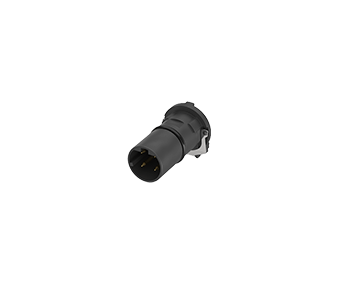

INQURY 216A-XXMSA

216A-XXMSA M12 Two Piece Insert, Push-Pull, A-Code, XXPin Male DIP

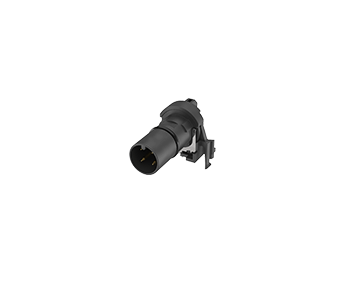

INQURY 216A-XXMRA

216A-XXMRA M12 Two Piece Insert, Push-Pull, A-Code, XXPin Male R/A DIP

INQURY 216A-XXFSA

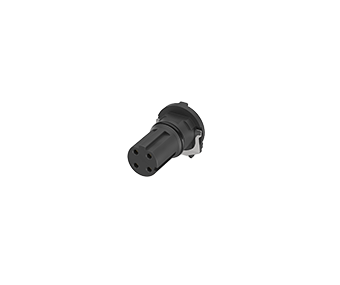

216A-XXFSA M12 Two Piece Insert, Push-Pull, A-Code, XXPin Female DIP

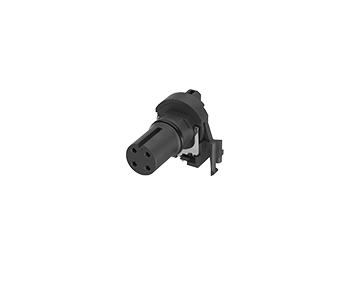

INQURY 216A-XXFRA

216A-XXFRA M12 Two Piece Insert, Push-Pull, A-Code, XXPin Female R/A DIP

INQURY 216X-08FSA

216X-08FSA M12 Two Piece Insert, Push-Pull, X-Code, 8Pin Female DIP

INQURY 216X-08FRA

216X-08FRA M12 Two Piece Insert, Push-Pull, X-Code, 8Pin Female R/A DIP

INQURY 216X-08FRA

216X-08FRA M12 Two Piece Insert, X-Code, 8Pin Female R/A DIP Type

INQURY 216X-08FSA

216X-08FSA M12 Two Piece Insert, X-Code, 8Pin Female DIP Type

INQURY 216D-XXFRA

216D-XXFRA M12 Two Piece Insert, D-Code, XXPin Female R/A DIP Type

INQURY 216D-XXFSA

216D-XXFSA M12 Two Piece Insert, D-Code, XXPin Female DIP Type

INQURY 216A-XXFRA

216A-XXFRA M12 Two Piece Insert, A-Code, XXPin Female R/A DIP Type

INQURY 216A-XXFSA

216A-XXFSA M12 Two Piece Insert, A-Code, XXPin Female DIP Type

INQURY 216D-XXMRA

216D-XXMRA M12 Two Piece Insert, D-Code, XXPin Male R/A DIP Type

INQURY 216D-XXMSA

216D-XXMSA M12 Two Piece Insert, D-Code, XXPin Male DIP Type

INQURY 216A-XXMRA

216A-XXMRA M12 Two Piece Insert, A-Code, XXPin Male R/A DIP Type

INQURY 216A-XXMSA

216A-XXMSA M12 Two Piece Insert, A-Code, XXPin Male DIP Type

INQURY 216A-XXMF1

216A-XXMF1 M12 A-Code, Male For Field Installable, Plastic

INQURY 216A-XXFF1

216A-XXFF1 M12 A-Code, Female For Field Installable, Plastic

INQURY 216A-XXFAR

216A-XXFAR M12 A Code Receptacle, Female Pins, Solder Type, Rear Fastened

INQURY 216A-XXMSF

216A-XXMSF M12 A Code, Male, Straight, Front Fastened

INQURY 216A-XXFAF

216A-XXFAF

.png)