What Is the M12 Connector?

.png) M12 connectors are robust, circular connectors. The "M" refers to the standardized metric thread designation of the connector, while the figure "12" indicates the outer diameter of the connector housing in millimeters (mm). They come in 2- to 17-pin configurations for data or power applications, and are typically found at the end of PUR or PVC jacketed cables.

M12 connectors are robust, circular connectors. The "M" refers to the standardized metric thread designation of the connector, while the figure "12" indicates the outer diameter of the connector housing in millimeters (mm). They come in 2- to 17-pin configurations for data or power applications, and are typically found at the end of PUR or PVC jacketed cables.

The exact geometry and conductor specifications of M12 connectors are usually standardized by the International Electrotechnical Commission (IEC). For instance, threaded M12 connectors for high stability are defined as per IEC 61076-2-101. On the other hand, push-pull M12 connectors for quick installation follow IEC 61076-2-010 (2021) or manufacturer-specific standards.

Besides, due to their compact size, high versatility, and resistance to environmental factors (such as vibration, dust, and moisture), these connectors are designed for a wide range of industrial applications and ensure safe operation. They also provide easy installation and built-in shielding against disruptive EMI/RFI signals, ideal for the current industrial setting. Common use cases include factory automation, industrial internet of things (IIoT) systems, sensor connections, Ethernet networks, and 5G infrastructures.

Understanding M12 Connection: M12 Connector Codes and Pin Layout Types

M12 connectors can handle a wide range of signals and power. They have different codes that determine the pin layout and signal type (what function each pin serves) of the M12 connection, as well as the number of pins for the M12 plug (male part) and M12 socket (female part).

The pin count options for M12 connectors include 2, 3, 4, 5, 6, 8, 12, and 17-pin variations. Furthermore, the coding options include A, B, C, D, and X-coding for data applications, and K, L, S, and T-coding for power applications. It's important to specify the right coding to ensure proper functionality and avoid connection errors between the M12 plug and the M12 socket.

With this in mind, here is an overview of the different M12 connector codes and their pin layout:

| M12 Connector Coding | |

|---|---|

A-Coding | A-coding is the most versatile of the M12 connector codes. 2 to 17 pin counts allow it to handle various applications, including sensors, actuators, DC power supplies, and 10/100 Mbps industrial Ethernet communications in some implementations. |

B-Coding  | B-coding is primarily designed for fieldbus systems, such as Profibus, which link sensors, actuators, and controllers within a distributed automation network. Typically featuring 5 pins, B-coded connectors have a standardized pin layout for power and fieldbus data transmission. |

C-Coding | C-coding (also referred to as Micro-AC) features a dual keyway design and caters to AC power applications. These connectors are optimized for powering smaller automation components, like compact motors, drives, and distributed I/O modules. |

D-Coding | D-coding is specifically tailored for industrial Ethernet applications requiring data transmission up to 100 Mbit/s. These connectors usually have a 4-pin arrangement, accommodating two twisted pairs for data communication. Instead of power delivery, D-coded connectors focus on reliable signal transmission. |

X-Coding | X-coding is engineered for high-speed industrial Ethernet, supporting data rates up to a blazing 10 Gbit/s. To handle this increased bandwidth, X-coded connectors feature an 8-pin configuration. They are ideal for demanding applications that require fast and reliable data transfer, like real-time video monitoring systems or high-precision machine control, as well as base stations and edges devices in 5G infractstuctures. |

K-Coding.png) | Designed for high-power DC applications, K-coded M12 connectors typically feature 4 or 5 pins, supporting up to 12A and 630V. They are ideal for electric vehicle charging and high-power industrial equipment. |

L-Coding | Designed for AC power transmission, L-coded M12 connectors often feature 4 or 5 pins. They can handle higher voltages and currents, making them suitable for motors, drives, and other power-hungry equipment. |

S-Coding | S-coded M12 connectors are also used for AC power applications. They come in 3 to 5-pin variations designed for lighting or machinery requiring high voltages and currents in industrial settings. |

T-Coding | Primarily used for DC power applications, T-coded M12 connectors come in 2 to 4-pin configurations optimized for carrying higher currents and voltages. This makes them suitable for powering DC actuators, sensors, and other devices in industrial environments. |

What Is the Difference Between M12, M8, and other M Series Connectors?

M12 and M8 connectors have become popular choices with the rise of industrial automated systems, due to their compact size and transmission ability. Other prevalent options among M series connectors include the M5 and M23. The main difference between the four of these connectors is their shell diameter and the number of pins. In turn, they can handle varying power and signal transmission.

For applications where space is at an absolute premium, M5 connectors offer a miniature design with a 5mm shell diameter. These connectors are best suited for low-power and low-signal applications, typically handling currents up to 2A. They find their niche in small sensors, data acquisition systems, and other compact control systems, but are limited to A-coded equipment.

M8 connectors, with their 8mm shell diameter, are also compact and cost-effective solutions for space-constrained devices. They typically offer 3 to 8 pins, with more coding options than M5 connectors. While ideal for smaller sensors and basic control systems, M8 connectors have limitations in power handling and the number of available connections.

Consequently, the 12mm diameter of M12 connectors allows them to handle higher power loads and a greater number of pins (up to 17) compared to M8 connectors. This increased capacity, combined with superior water resistance, makes M12 connectors a versatile choice for a wide range of industrial applications, including those involving moisture, such as measurement, food and beverage, and robotics.

At the other end of the spectrum, M23 connectors, with their 23mm shell diameter, are the largest and most powerful in the M series. Designed for high-power applications, they can handle significant current loads (up to 63A) and multiple signal lines. M23 connectors are ideal for heavy machinery, high-power motors, and demanding industrial automation systems.

Ultimately, the choice between M series connectors boils down to your specific requirements. Here’s a brief comparison:

| M5 Connector | M8 Connector | M12 Connector | M23 Connector | |

|---|---|---|---|---|

| Shell Diameter | 5 mm | 8 mm | 12 mm | 23 mm |

| Connection Density | 2-4 pins | 4-8 pins | 2-17 pins | 3-19 pins |

| Key Advantages | Smallest size, lowest cost | Compact size, lower cost | Good power-to-size ratio, more connection options, robust design | Highest power, more connection options, robust design |

| Considerations | Low power, limited signals | Limited power and data, fewer pins | Larger size, potentially higher cost | Bulky size, highest cost |

| Coding Systems | A-coded only (for simple signal applications) | A-coded, D-coded (for Ethernet), B-coded (rarely) | A-, B-, C-, D-, X-coded (for data); K-, L-, S-, T-coded (for power) | Not standardized (power/signal hybrid per vendor) |

| Typical Use Cases | Small sensors, tight-space signal transmission | Basic control systems, small actuators | Industrial automation, robotics, harsh environments | Motors, robotics, servo drives, CNC machines |

The Advantages of Using M12 Connectors

M12 connectors have revolutionized industrial automation by offering a robust and versatile solution compared to traditional wiring methods. With various pin configurations and coding options, M12 connectors can cater to a wide range of signal and power transmission requirements. Their unique design translates into a multitude of benefits, driving their widespread adoption. Further benefits include:

Unmatched Ruggedness for Harsh Industrial Environments

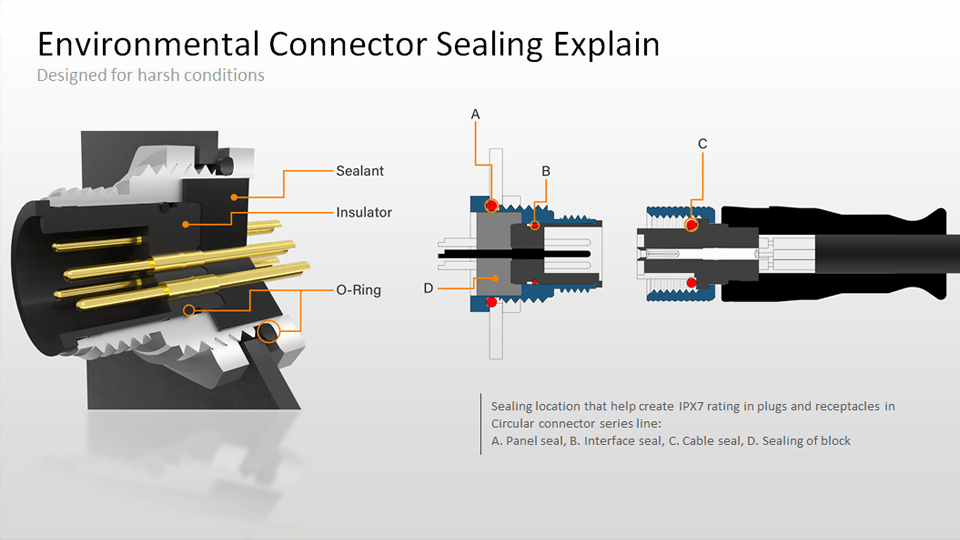

M12 connectors outperform the common RJ45 in harsh environments. Their IP67-69 components withstand dust, moisture, vibrations, and extreme temperatures.

Constructed from robust materials like gold plating and beryllium copper contacts, these connectors can also withstand hundreds of mating cycles without compromising performance, reducing downtime.

Superior EMI/RFI Shielding to Prevent Signal Disruptions

Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) are external signals that derive from electronic devices, and without proper EMI/RFI shielding, these signals will disrupt the transmission of connectors or other sensitive areas, leading to inaccurate data collection and hindered process control.

The EMI/RFI shielding of M12 connectors is created with materials that reduce unwanted electromagnetic signals. Common shielding materials include nickel-plated brass and zinc die-cast with conductive plating. There are also fully shielded cables with braided tinned copper shields. These metal shieldings act as a physical barrier for M12 connections, which can reflect or absorb disruptive signals, ensuring the integrity of data and power transmission.

Effortless Installation

Most M12 connectors feature a push-pull mechanism, allowing it to be inserted and removed easily without tools, as all you have to do is apply or release pressure in a specific direction. It is compact and enables fast operation, reducing installation time up to 80%, as well as labor costs in the process.

Another popular variation is M12 connectors with threaded coupling mechanisms. They can be screwed in by hand quickly and easily, while the threaded design offers excellent stability, making it highly reliable in applications where frequent vibrations are involved.

Optimal Size and Capabilities for Industry 4.0 Applications

With the rise of Industrial Internet of Things (IIoT) and Industry 4.0, the role of M12 connectors has become more critical. Their compact 12mm diameter is one of the main reasons for this wide application, along with their superior performance, durability, and lower maintenance costs. M12 connectors also have higher versatility, allowing them to seamlessly integrate with various industrial devices and systems, ultimately creating an interconnected industrial Ethernet environment.

Common Applications of M12 Connectors

The application of M12 within industrial automation is sophisticated, from data transfer to power delivery between sensors, network components, and critical equipment. As technology continues to evolve, M12 connector innovation keeps pace, catering to other diverse industries like robotics, alternative energy, 5G infrastructure, smart agriculture, and more.

-

Sensor and Actuator Connections: M12 connectors, particularly A-coded versions, are widely used to connect sensors (measuring temperature, pressure, etc.) and actuators (controlling valves, robots, etc.) to control systems, ensuring accurate data collection and precise control of automated processes.

-

Industrial Ethernet: As industrial communication relies more on Ethernet, M12 connectors become essential. D-coded M12 connectors support standard Ethernet speeds, while X-coded versions handle high-speed Gigabit Ethernet for demanding applications like real-time video and complex machine control.

-

Fieldbus Systems: Specialized industrial networks like Profibus and Interbus require M12 connectors, often B-coded, to facilitate communication between various devices and maintain reliable data exchange.

-

Power Supplies: While T-coded connectors can handle some DC power, L-coded and S-coded M12 connectors are designed for AC power applications, supplying power to various industrial equipment.

-

Robotics: The robust design of M12 connectors provides reliable signal and power transmission required in robotic applications. This allows for seamless control and precise movements.

-

Alternative Energy: Solar and wind farms utilize M12 connectors within sensors, controllers, and data acquisition systems. Their ability to withstand harsh weather conditions ensures reliable operation in these remote locations.

- Transportation: The M12 connectors’ resistance to vibration and shock ensures reliable performance in mobile environments. Hence, they are ideal for connecting sensors, control systems, and communication networks in railway systems or other commercial vehicles.

- 5G Infrastructure: M12 connectors are crucial for the high-speed and reliable connections demanded by 5G networks. Specifically, X-coded M12 connectors facilitate 10 Gigabit Ethernet for data-intensive applications such as base station communication and remote radio units, while D-coded versions provide efficient standard Gigabit Ethernet for network management and monitoring devices.

- Smart Agriculture: As smart agriculture systems increasingly depend on automated sensing and control, M12 connectors become essential as well. For instance, A-coded M12 connectors are ideal for versatile sensor and actuator connections in applications like soil monitoring and irrigation control, while D-coded versions ensure efficient Ethernet communication for data transmission between distributed farming devices.

By choosing M12 connectors, operations become equipped with a leading solution for future-proofed infrastructures.

How to Select the Right M12 Connector?

Choosing the right M12 connector for your application requires careful consideration beyond simply following equipment recommendations. While manufacturer data sheets provide a starting point, with details such as product material, cable assembly method, etc, it's crucial to select a high quality connector with power and temperature ratings that exceed your equipment's absolute maximum requirements to ensure safe operation.

Material

As we’ve mentioned earlier, materials with signal attenuating properties are crucial for the M12 connector’s EMI/RFI shielding, so be sure that silver or silver alloys are incorporated for proper protection against disruptive electromagnetic signals. The material of your M12 connector shell also plays a critical role in its durability and performance. Common materials for the shell include plated brass, stainless steel, and various other alloys.

Nickel-plated brass is the most popular choice for M12 shells as brass offers good conductivity, while the nickel plating provides durability and excellent resistance to corrosion, while being affordable. Stainless steel on the other hand, offers superior strength, corrosion resistance, and washability for environments with extreme temperatures, high pressure, or aggressive chemicals. Some M12 are made with different alloy variations to achieve specific properties such as enhanced strength, improved corrosion resistance, or better machinability, you may consult your manufacturer for detailed information on the alloy.

For the contact pins, copper is used to provide excellent conductivity. There are also some M12 connectors that include a lightweight, high-performance thermoplastic casing to provide better insulation and limit the connector’s exposure to harsh elements

Power and Temperature Ratings

Identify the absolute maximum power your device consumes and its operating temperature range before choosing a M12 connector, as this will impact the overall performance capabilities. Once you have determined these factors, opt for a connector with higher ratings to provide a safety margin. This buffer ensures reliable operation even under unexpected fluctuations or peak conditions.

Environmental Considerations

We previously discussed IP ratings, which indicate the level of protection against dust and liquids. Consider this when choosing an M12 connector with an IP rating suitable for the anticipated level of contact and water exposure in your application.

Moreover, if your equipment may be subjected to shock or high vibrations, be sure to select a connector known for its resistance to physical impact.

For harsh environments with chemicals or corrosive elements, it is also advisable to ensure the connector housing material offers superior corrosion resistance, to prevent risk of damage and electrical hazards.

Brand and Quality

M12 connectors are critical components in industrial systems. Selecting a reliable brand with a reputation for high-quality products is essential for ensuring long-term performance and minimizing downtime.

For instance, ATTEND offers a comprehensive selection of M12 connectors within its M Series, all rigorously tested to meet strict industry standards, as we are committed to providing you with the best connector solution for your industrial application.

FAQs About PCB Connectors

Q1. What cables to use for M12 connections?

- Twisted Pair Cables: Mostly used for data transmission, especially in Ethernet and Fieldbus systems.

- Ethernet Cables (like Cat5e or Cat6a): Commonly used for network connectivity to ensure stable and fast communication with appropriate data speeds.

- Power Cables (High-Current Load Variations): Ideal for power distribution, carrying the necessary current to devices safely.

Q2. What does the IP rating mean in M12 connectors?

- IP67: Signifies that the connector is completely dust-tight, has complete protection against contact for up to 8 hours, and can withstand powerful water jets from any direction, as well as temporary immersion up to 1 meter for 30 minutes. It is ideal for applications involving frequent exposure to dust, washdowns, splashes, or temporary underwater use.

- IP68: Indicates that the connector has the same resistance against solids and water jets as the IP67 rating, while also being able to withstand prolonged immersion in water up to 1.5 meters for 30 minutes, making it ideal for environments prone to occasional flooding.

- IP69K: Not only are IP69-K-rated M12 connectors dust-tight, but they can also endure high-pressure, high-temperature water jets commonly used in industrial cleaning processes. This makes them perfect for the food and beverage industry, chemical plants, or any applications that require frequent rigorous cleaning.

Q3. How to maintain M12 connectors from debris and moisture?

- Inspect and clean the mating surfaces (using compressed air or isopropyl alcohol) frequently to remove dirt, dust, or metal particles that can affect electrical contact.

- Always use protective caps or covers when connectors are not in use to block contaminants.

- Ensure connectors are properly aligned during mating to avoid trapping debris inside.

- Select M12 connectors with suitable IP ratings (such as IP67 or higher) based on your environment.

- Use proper sealing techniques, like cable glands or conduit fittings, to prevent moisture ingress.

- Avoid disconnecting connectors in humid or wet conditions, and routinely check for corrosion or damage, replacing components as needed.

Q4. RJ45 V.S. M12 connector: which one to choose for ethernet applications?

| Feature | RJ45 Connector | M12 Connector |

|---|---|---|

| Industry Adoption | Common in office, commercial buildings, and data center networks (legacy and general Ethernet use) | Increasingly deployed in industrial automation, robotics, transportation, agriculture, and other Industry 4.0 applications |

| Design & Form Factor |

|

|

| Standardization | Defined by IEC 60603-7 (Category 5 to 8 Ethernet standards) |

|

| Compatibility |

|

|

| Environmental Protection |

|

|

| Durability |

|

|

| Ideal Environment | Indoor environments with stable conditions and minimal mechanical stress | Harsh industrial, outdoor deployments, transportation systems, food and beverage processing, and high-vibration machinery |

Why ATTEND’s M Series Connectors Are the Ideal Choice

ATTEND is a leading provider of advanced connectivity solutions, offering a wide range of connectors and cables, such as memory card sockets, PCB card sockets, I/O connectors, and cable assemblies. Our products are used in diverse sectors, including industrial, networking, transportation, and consumer electronics.

We deliver top-quality M series connectors, including:

- Wide range of options: Multiple types of code and high compatibility for various equipment.

- Superior materials: Durable construction for long-lasting performance.

- Flexible Assembly: Offering ready-to-use over-molded and customizable on-site assembly cable options, catering to diverse needs.

- Versatile mounting methods: The socket can be mounted onto front and rear panels through different methods, including through-hole and surface mount.

- Waterproof options: Ideal for washdown environments.

- Strict quality control: Ensures reliable performance and safety.

But what sets us apart? It's simple: quality, service, and reach.

Quality you can trust: We are committed to providing exceptional products. That's why we implement strict quality checks and partner with trusted vendors to ensure every M12 connector meets the highest standards. And with a variety of customization options, we can tailor the perfect solution for your specific needs.

Service that exceeds expectations: At Attend, we believe in fostering strong relationships with our customers. Our dedicated sales and technical team is available around the world to answer your questions and guide you toward the right products. We offer a wealth of resources to help you make informed decisions, ensuring you get the most out of your M12 connectors.

Reaching you wherever you are: With a global network spanning numerous countries, we ensure our M12 connectors are readily accessible wherever you operate. No matter where your project takes you, Attend is there to connect you with the solutions you need.

Reach Out to Us and discover the power and versatility of M12 connectors.

Choose ATTEND's M series for your next project and experience the difference!

Jaime Coreano VP of Sales, North America Jaime has been a driving force at ATTEND, using his 20+ years of experience in semiconductor and electronic components sales throughout the Americas to help our customers grow and innovate. He knows his stuff when it comes to Power Supplies, Connectors, Memory, Frequency Products, LEDs and more. Jaime’s knack for creating and executing winning sales and marketing strategies has made him a standout in Markets like Networking, Industrial, Mil/Aero, Medical, Computing and more. His industry smarts and strategic thinking are key to ATTEND’s ongoing success and growth. |

Read More:

➤ Guide for M.2 SSD Types, Protocols, and Key Configurations

➤ PCB Connector Types, Functions, and Selection Tips

.png)