Engineer's Guide to IP Rating Selection

According to industry statistics, over 50% of equipment failures in outdoor and industrial environments stem from non-electrical factors, with moisture, dust, temperature variations, and cleaning processes being the primary causes. Therefore, when planning connectors, structural components, or overall system design, the first question engineers need to clarify is: "Does this product require IP67, IP68, or IP69K?"

However, many design teams have the misconception that "higher IP ratings are always better." In reality, selecting an excessively high protection level leads to unnecessary cost increases and design complexity, while insufficient protection may result in massive product returns and field failures. This article systematically explains IP code testing standards, technical details engineers often overlook during selection, corresponding strategies for different application scenarios, and ATTEND's design experience in actual projects.

IP Code Structure Analysis: How IEC 60529 Defines Dust and Water Protection

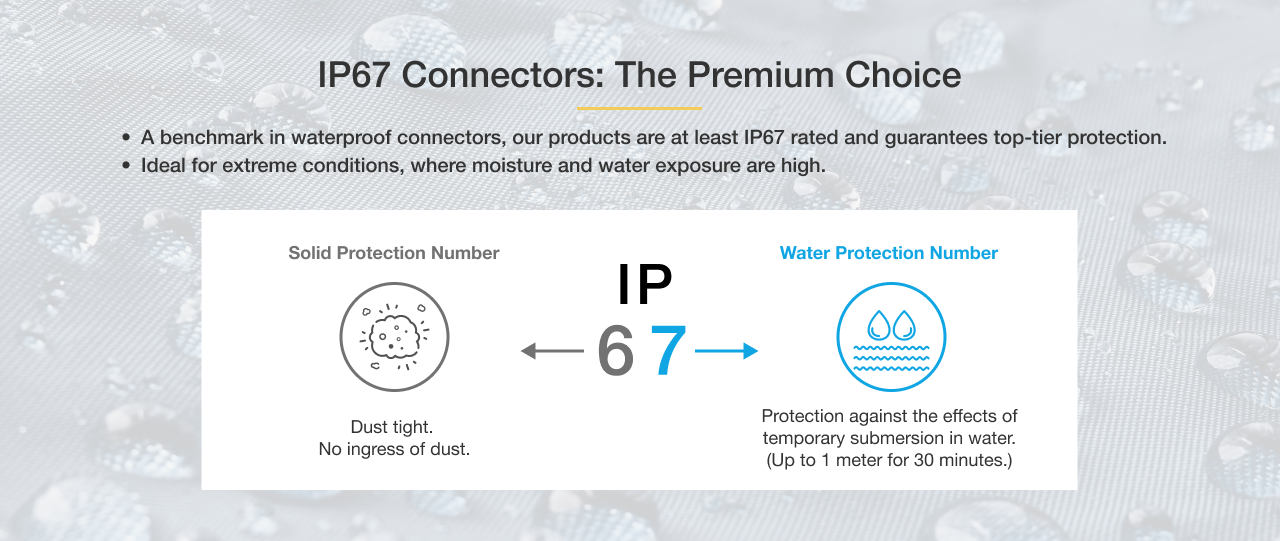

IP (Ingress Protection) codes indicate equipment's protection capability against solid foreign objects and liquids, as defined by the International Electrotechnical Commission's IEC 60529 standard. IP is followed by two digits: the first indicates dust protection level (0–6), and the second indicates water protection level (0–9K). It's important to note that these two digits don't have a linear relationship—different numbers correspond to completely different testing conditions.

The first digit defines dust protection capability. Level 5 means "Dust Protected," allowing minimal dust ingress without affecting functionality; Level 6 means "Dust Tight," ensuring no dust can enter any internal space. Industrial equipment and connectors typically require at least IP5X or IP6X to operate reliably in production lines or outdoor environments.

The second digit defines water protection capability. Common levels include: Level 7 (immersion at 1-meter depth for 30 minutes), Level 8 (prolonged deep water immersion with specific conditions defined by manufacturers), and Level 9K (high-pressure hot water jet at close range, following ISO 20653). These three levels are the most commonly encountered specifications during selection and are also where most technical misunderstandings occur.

The Difference Engineers Care About Most: IP67 vs IP68

When evaluating environmental protection capabilities of connectors or structural components, IP67 and IP68 are often confused, but they differ significantly in testing conditions and application scope.

IP67 uses fixed testing conditions. According to IEC 60529's explicit requirements, the test method involves immersing the product in 1-meter-deep water for 30 minutes. This condition has no flexibility, making it suitable for applications encountering brief immersion or rain exposure, such as outdoor IoT devices, surveillance cameras, handheld terminals, and industrial sensors. When a product indicates IP67, its testing conditions are clear and verifiable.

IP68, however, is a floating specification. IEC 60529 only requires "protection capability must exceed IP67," but specific immersion depth and duration must be jointly defined by manufacturers and customers. Therefore, IP68 could represent 1.5 meters for 1 hour, or 3 meters for 72 hours, or even more stringent conditions. This means different manufacturers' claimed IP68 capabilities may vary tremendously.

Designing IP68-rated products typically requires higher-grade sealing materials (such as fluorocarbon O-rings), thicker sealing structures, and stricter process control (including airtight testing). Simply put, IP67 is a standardized specification, while IP68 is a customized specification. Engineers must require manufacturers to provide clear testing conditions and verification reports during selection; otherwise, the IP68 designation lacks substantial reference value.

IP69K: Highest Water Protection, Designed for High-Pressure Hot Water Cleaning Environments

IP69K is currently the most stringent water protection standard, originating from ISO 20653 (replacing the original DIN 40050-9). This rating primarily targets environments requiring high-pressure hot water cleaning, including food processing equipment, construction vehicles, agricultural machinery, and other industrial devices requiring regular high-pressure washing.

IP69K testing conditions include: using 80–100 bar (1160–1450 psi) high-pressure water jets at 80°C, with nozzles positioned 10–15 cm from the test object, spraying from 0°, 30°, 60°, and 90° angles while the test object rotates to ensure comprehensive force exposure. This test intensity far exceeds typical water protection testing ranges.

It's particularly important to note: IP69K does not equate to immersion protection capability. If a product isn't simultaneously marked "IP67/IP69K" or "IP68/IP69K," it cannot guarantee prolonged water immersion resistance. In other words, products passing IP69K testing can withstand high-pressure hot water washing but may not survive prolonged immersion in still water without ingress. This is because the two tests evaluate completely different physical conditions.

Designing IP69K-rated products requires multiple sealing structures (such as dual O-rings or overmolded encapsulation), high heat and pressure-resistant materials, and precise mechanical locking design. Manufacturing processes must execute airtight or differential pressure testing to ensure all components can withstand extreme conditions.

Real-World Applications: How ATTEND Connectors Correspond to Different IP Ratings

In practical applications, different product types and usage environments correspond to different IP rating requirements. For example, in industrial automation, M8 and M12 series connectors are typically designed as IP67 or IP68. These connectors are widely used in AGVs (Automated Guided Vehicles), robotic arms, and outdoor sensors, which encounter rain, dust, oil mist, vibration, and high-frequency mating/unmating during operation. Therefore, M-series connectors use metal threaded designs with O-ring sealing, cable ends employ overmolding processes, and can customize IP68 immersion depth and duration according to customer requirements.

Another typical application is outdoor charging stations and handheld terminals, which often use waterproof magnetic pogo pin designs with IP67 or IP68 protection ratings. The advantage of magnetic structures is reducing misalignment risk during mating and sealing damage probability, making them suitable for industrial handheld devices, measurement instruments, and medical equipment. Design priorities for these products include: sealing coordination between pins and housing, deburring of metal components (to avoid O-ring damage), and consistency control of base potting and cable harness sealing.

ATTEND's product line covers industrial automation, outdoor equipment, and handheld terminals, providing comprehensive protection solutions for IP67 and IP68 ratings. From connector body sealing design and cable-end overmolding processes to cable harness potting, we ensure consistent protection standards across all system components, rather than merely testing individual parts for verification.

Common Misconceptions (Technical Details Engineers Often Overlook)

Misconception 1: IP Ratings Have a Linear Hierarchy

Many engineers believe IP68 is superior to IP67, and IP67 superior to IP66, but this is actually incorrect. IP66 tests water spray resistance, while IP68 tests immersion resistance—they evaluate completely different physical conditions and cannot be directly compared.

Misconception 2: IP68 Automatically Includes IP66 Protection

This is a common false assumption. Unless a product explicitly indicates "IP66/IP68" and has passed both tests, IP68 products may not pass IP66 spray testing. Protection ratings have no automatic inclusion relationship.

Misconception 3: Water Protection Equals Condensation Prevention

IP rating tests external water ingress but cannot prevent internal moisture condensation caused by temperature differences. Addressing condensation requires additional design measures, including vents, appropriate potting, or reducing relative distance between signal lines and cavities. These design details are outside IP testing scope.

Misconception 4: IP69K Means Prolonged Immersion Capability

As previously stated, IP69K only guarantees resistance to high-pressure spray, not prolonged immersion. If application scenarios require both capabilities simultaneously, products must pass dual certification.

Selection Guide: Appropriate IP Ratings for Different Equipment

Indoor consumer devices typically require only IP54 rating, which provides basic splash protection. General outdoor equipment should achieve at least IP67 standard to handle rainfall and accidental immersion.

Equipment with prolonged outdoor exposure, such as surveillance cameras or communication base stations, should select IP67 or IP68, as these devices need to resist continuous moisture ingress and UV aging. Underwater devices must use IP68 rating, but immersion depth and duration conditions must be clearly defined.

Food processing equipment, construction vehicles, and agricultural machinery requiring high-pressure hot water cleaning environments must select IP69K standard. Outdoor charging stations typically design for IP67 or IP68 ratings due to high-frequency mating/unmating, magnetic mechanism operation, and rainfall exposure.

IP Rating Selection Reference Table

| Application Type | Recommended IP Rating | Typical Environmental Conditions | Design & Selection Priorities |

|---|---|---|---|

| Indoor Consumer Electronics (Appliances, General IT Equipment) | IP54 | Light dust, daily splashing, brief humid environments | Basic dust/splash protection sufficient, balancing cost and thermal design |

| General Outdoor Equipment (Surveillance Cameras, Outdoor IoT) | IP67 | Rain exposure, brief immersion, prolonged humidity and temperature variations | O-ring sealing, cable exit potting and harness fixation, UV and aging assessment |

| Long-term Outdoor & Underwater Equipment (Base Stations, Dock Equipment, Sensors) | IP67 / IP68 (conditions must be defined) | Extended rain exposure, standing water, possible immersion at certain depth and duration | Clearly define IP68 immersion depth and duration with suppliers, requires airtight testing and advanced sealing materials |

| Food Processing Equipment, Construction Vehicles, Agricultural Machinery | IP69K or IP67/IP69K | High-pressure hot water cleaning, detergents, oil, mud and vibration | Enhanced mechanical locking, dual sealing structures, material heat and chemical resistance, confirm if immersion capability is also needed |

| Outdoor Charging Stations, Industrial Handheld Terminals, Waterproof Magnetic Interfaces | IP67 / IP68 | Frequent mating/unmating, magnetic alignment, rain and humid environments | Pin and housing coordination, tolerances and deburring, cable harness overmold and potting consistency |

FAQ

During actual use, phones may encounter:

- Instantaneous pressure peaks from arm movements or diving

- Prolonged immersion exceeding test specifications

- Degraded sealing performance from housing aging, scratches, or drops

- Some IP68 products might only be 1.5 meters for 30 minutes

- Others could be 3 meters for 72 hours, or customized for specific applications

- Immersion depth (how many meters)

- Immersion duration (minutes/hours/days)

- Test medium (fresh water, salt water, oil, etc.)

- IP67: Tests prolonged still water immersion capability (1 meter, 30 minutes)

- IP69K: Tests high-pressure, high-temperature, close-range spray capability (following ISO 20653)

If a product is simultaneously marked IP67/IP69K, it means it passed both immersion testing and high-pressure washing testing;

If only marked IP69K, you cannot assume it can withstand prolonged immersion without water ingress.

- Condensation from temperature differences: Day-night temperature variations or equipment heat causes internal moisture to condense into water droplets at cold points—this is outside IP testing scope.

- Long-term aging: UV, ozone, and chemical agents cause plastic components and O-rings to age and harden, reducing sealing performance.

- Mechanical stress and mating fatigue: Frequent mating/unmating, cable pulling, or impact may deform or loosen sealing surfaces.

- Improper cable harness and endpoint handling: While connector bodies pass IP testing, cable exit points, potting areas, or improper customer-end assembly can still create "water ingress paths."

IP Rating Is Only the Starting Point, Not the Endpoint

IP rating is an important reference indicator for product protection design, but it's only the starting point, not the endpoint. Factors truly affecting protection capability include: sealing design (material selection and configuration of O-rings or gaskets), material properties (heat resistance, UV resistance, chemical resistance), cable harness and terminal encapsulation processes, and pressure testing and quality control during assembly.

When planning IP ratings for connectors or housings, it's recommended to first clearly define usage scenarios: Does the product need water immersion? If so, what depth and duration? Does it need to withstand high-pressure spray? Will it encounter temperature variations or chemical corrosion? After clarifying these conditions, discuss complete testing conditions and verification reports with suppliers to ensure selection of truly appropriate protection ratings.

Need to Select IP Rating for Your Next Project?

If you need to evaluate appropriate IP ratings based on project requirements, or require technical consultation for M12 connectors, waterproof magnetic pogo pins, or outdoor cable harnesses, welcome to discuss actual application environments and testing requirements with our engineering team. We can assist from specification definition, sample verification to mass production, ensuring every protection rating truly corresponds to field requirements.