Keeping Trucks, Trackers, and Industrial Devices Connected Across Continents

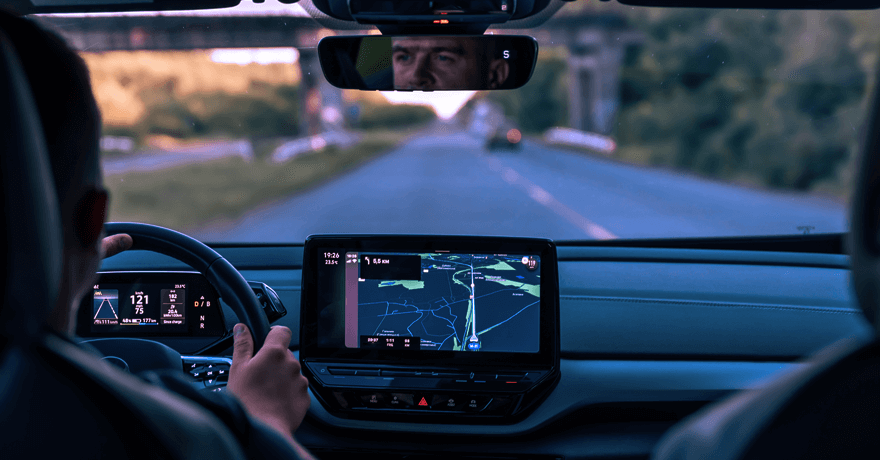

Picture this: A delivery truck crosses three countries in a single day. An AI-powered dash cam captures every turn, every sudden brake, every near-miss. Meanwhile, a compact tracker tucked inside a pharmaceutical container monitors temperature fluctuations down to the decimal. Both devices share a common thread—they're constantly talking to the cloud, sending critical data that keeps operations running smoothly.

But here's what most people don't see: behind every successful data transmission sits a small, precision-engineered component that makes it all possible. The SIM card connector.

The Invisible Infrastructure

In the world of IoT, we often celebrate the flashy stuff—the AI algorithms, the sleek hardware designs, the sophisticated dashboards. Yet the real magic happens at the intersection of hardware and network, where a tiny connector ensures your device stays online, day after day, mile after mile.

SIM cards do more than just store a phone number. In IoT devices, they're the gateway to the entire cellular network. They authenticate the device, establish secure connections, and enable the data flow that powers everything from real-time fleet tracking to cold chain monitoring. Without a reliable way to hold and connect that SIM card, even the most advanced IoT device becomes a paperweight.

Two Worlds, Same Challenge

Walk into any telematics company's engineering lab, and you'll find two distinct philosophies playing out in their product lines.

On one side, there are the vehicle-mounted systems—dash cams, telematics gateways, fleet management hubs. These devices live in harsh environments: constant vibration, temperature swings from freezing winters to scorching summers, and the occasional pothole that rattles everything loose. For these applications, engineers still turn to the Mini SIM format. It's larger, yes, but that size brings mechanical stability. The connector can grip firmly, withstand shock, and handle the punishment of commercial vehicle operations.

On the other side, you'll find the new generation of asset trackers—devices small enough to slip into a shipping container or attach to high-value cargo. Here, every millimeter matters. These designs demand Nano SIM connectors, which occupy a fraction of the PCB space while maintaining the same level of reliability. It's a masterclass in miniaturization without compromise.

What's fascinating is that despite their size difference, both connector types face the same fundamental challenge: they must work flawlessly, often for years, with zero tolerance for failure.

Where Connectors Meet Real Life

Let's talk about where this actually matters in practice.

In the Fleet

Modern commercial vehicles are essentially computers on wheels. That AI dash cam isn't just recording video—it's analyzing driver behavior in real time, detecting drowsiness, identifying unsafe following distances, and even predicting potential accidents before they happen. But all that intelligence is worthless if it can't reach the cloud.

The SIM connector enables the constant two-way communication that makes these safety systems work. It's pushing video streams upstream and pulling down firmware updates, route changes, and emergency alerts. In an industry where a prevented accident can save lives and millions in liability, connector reliability isn't a nice-to-have—it's mission-critical.

On the Road (or Sea, or Air)

Asset tracking has evolved far beyond "where is my package?" Today's logistics operations track not just location, but condition. Is the refrigerated container maintaining proper temperature? Has the shipment experienced any unusual shocks or movements? Did someone tamper with the seal?

These trackers run on battery power, often for months or years at a time. They need to be small, lightweight, and rugged. The Nano SIM connector makes this possible—providing enterprise-grade cellular connectivity in a package that weighs grams and draws minimal power. When a pharmaceutical company ships temperature-sensitive vaccines across continents, it's this tiny connector that enables the real-time monitoring that ensures product integrity.

Beyond Transportation

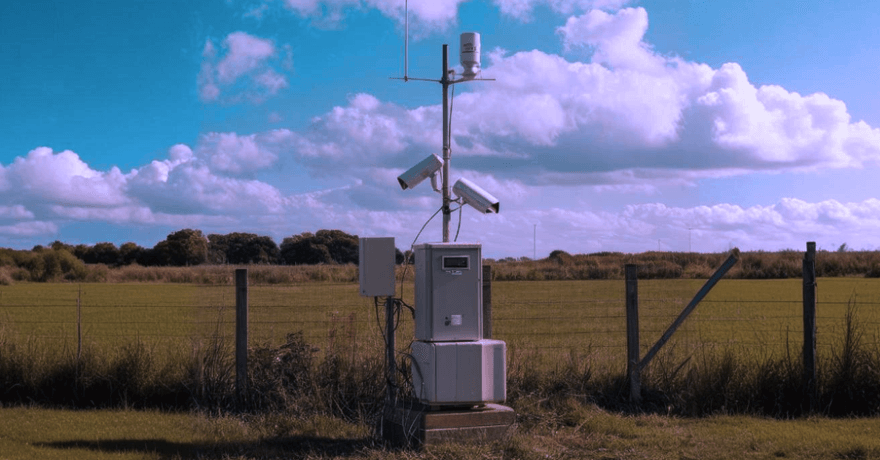

The applications extend far beyond what moves. Smart meters reporting energy consumption, industrial sensors monitoring equipment health, remote environmental monitoring stations—all rely on cellular connectivity, and therefore, on SIM connectors. In many of these deployments, the device might be installed once and left untouched for a decade. The connector needs to just work, year after year, with no maintenance.

Engineering for the Long Haul

So what makes a good SIM connector? It's not as simple as "holding a SIM card."

.png)

Product Selection Strategy: Mini and Nano SIM Connectors

In IoT design, SIM connector selection must balance environmental durability, size constraints, and operational needs. Below, we explore Mini and Nano SIM connectors and their applications.

.png)

Mini SIM (2FF) Connectors

Mini SIM connectors are ideal for vehicle-mounted systems facing harsh conditions.

- Mini SIM (2FF): Offers mechanical stability, vibration resistance, and reliable contact for dash cams and fleet management hubs.

Nano SIM (4FF) Connectors

Nano SIM connectors cater to compact, battery-powered devices requiring minimal PCB space.

- Nano SIM (4FF): Compact design with low power draw, ideal for asset trackers and cold chain monitoring.

Why Physical SIMs Persist

Yes, there's been plenty of discussion about eSIM technology replacing physical SIM cards. And it's true—eSIM has found its niche, particularly in consumer electronics where over-the-air provisioning streamlines user experience.

But walk through an industrial IoT deployment, and you'll quickly understand why physical SIM cards remain the pragmatic choice. The reasons aren't just technical—they're operational.

- Operational Simplicity: Consider a logistics company operating across Southeast Asia. Their trackers move between Indonesia, Thailand, Vietnam, and the Philippines—each with different carriers, different network conditions, and different regulatory requirements. When a device needs to switch carriers, a field technician can swap a physical SIM in minutes. With eSIM? You're dealing with remote provisioning systems, carrier partnerships, and potential compatibility issues. In a warehouse in Jakarta at 2 AM, simplicity wins.

- Longevity: Industrial IoT devices aren't smartphones that get replaced every few years. They're assets that need to operate reliably for 5 to 10 years, sometimes longer. eSIM standards, while maturing, are still evolving. Network support varies by region and carrier. Backward compatibility isn't guaranteed. Physical SIM connectors, by contrast, have decades of proven reliability. The 2FF and 4FF standards aren't changing—what works today will work in 2030.

- Harsh Environments: A Nano SIM connector is a purely mechanical, passive component. No firmware to fail, no protocols to negotiate, no remote configuration to go wrong. In a vehicle experiencing constant vibration, or a sensor exposed to temperature swings of 100°C, that simplicity is a feature, not a limitation. The connector either makes contact or it doesn't—and good ones make contact reliably, year after year.

- Cost and Control: Cost matters too, especially at scale. For manufacturers producing thousands or tens of thousands of devices annually, integrating a reliable SIM connector into the design is straightforward and economical. The supply chain is mature, the testing protocols are established, and the failure modes are well understood. eSIM infrastructure requires carrier relationships, provisioning systems, and ongoing management overhead. For many industrial applications, that complexity simply doesn't pencil out.

- Operator Control: Perhaps most importantly, physical SIM cards give operators control. If a device is misbehaving, if network performance degrades, if a carrier relationship sours—swapping a SIM card provides an immediate solution. It's tangible, it's fast, and it doesn't require a software engineer. In industries where downtime costs thousands per hour, that kind of hands-on flexibility is invaluable.

- eSIM vs. Physical SIM: This isn't to say eSIM doesn't have its place. For massive consumer deployments, for devices where physical access is truly impossible, or for applications requiring frequent network switching, eSIM makes sense. According to GSMA Intelligence, eSIM adoption in the consumer market has accelerated rapidly, with global connections doubling in 2023 and projected to double again in 2024 (exceeding 500 million shipments by year-end). Yet in industrial IoT applications, physical SIMs still account for approximately 70% of market share (2024 data), reflecting a pragmatic balance between technologies across different use cases.

Connectivity Technology Selection Reference Table

| Application Type | Connection Technology | Key Characteristics | Applicable Scenarios |

|---|---|---|---|

| Vehicle-Mounted Systems | Mini SIM (2FF) | Mechanical stability, vibration resistance | Dash cams, fleet management hubs |

| Asset Tracking | Nano SIM (4FF) | Compact, low power, reliable connectivity | Logistics trackers, cold chain monitoring |

| Industrial IoT | Mini/Nano SIM | Long-term reliability, waterproof | Smart meters, environmental sensors |

Critical Design Considerations

- Environmental Durability: Must handle vibration profiles, temperature cycling (-40°C to +85°C), and humidity without corrosion or loss of contact pressure.

- Contact Reliability: Survive thousands of insertion cycles with precisely calibrated spring tension to avoid intermittent connections or SIM card damage.

- Compact Design: Nano SIM connectors minimize PCB space while maintaining enterprise-grade connectivity for asset trackers.

- IP Rating Compatibility: Support IP67/IP68 enclosures for dust and water resistance without adding bulk.

Future Trends

Emerging Technologies

- Smart Connectors: Self-diagnostic connectors with predictive maintenance capabilities to enhance reliability.

- 5G/6G Integration: Support for next-generation cellular networks to handle higher data rates in IoT devices.

Standardization

Physical SIM standards (2FF, 4FF) ensure backward compatibility and longevity, while eSIM adoption grows in consumer markets, per GSMA Intelligence (2024).

The Bottom Line

The next time you see a delivery truck with an AI dash cam, or track a package in real-time on your phone, take a moment to appreciate the entire stack of technology making that possible. The GNSS satellites overhead are impressive, certainly. The AI algorithms running collision prediction are clever. The cloud infrastructure processing terabytes of fleet data is sophisticated.

But between all those brilliant pieces of technology—ensuring that data actually flows, reliably, continuously, through rain and snow and desert heat—sits a component most people never think about.

For companies building IoT devices, choosing the right SIM connector isn't just another line item on a bill of materials. It's a foundational decision that ripples through product reliability, field serviceability, warranty costs, and customer satisfaction. In industries where a single connectivity failure can mean a missed delivery, a compromised cold chain, or a safety incident, that little connector carries enormous responsibility.

The IoT revolution is powered by satellites, algorithms, and cloud computing. But it's held together—literally—by connectors. And as long as industrial devices need to move data across cellular networks in challenging environments, SIM card connectors will remain exactly where they've always been: at the heart of connectivity, doing their job quietly, reliably, and without fanfare.

The flashy technology gets the headlines. The connector gets the job done.

Core Recommendations

- Select for Application: Choose Mini SIM for vehicle-mounted systems and Nano SIM for compact asset trackers to match environmental needs.

- Prioritize Durability: Opt for connectors tested for vibration, temperature cycling, and IP67/IP68 ratings.

- Ensure Operational Simplicity: Physical SIMs provide flexibility for carrier swaps in industrial settings.

- Partner with Suppliers: Work with vendors offering robust SIM connectors and comprehensive support for faster deployment.