Complete Solutions from External I/O to Internal High-Speed Interconnects

Introduction

Not long ago, if you told me that AI would be running on factory floors, in traffic cameras, and inside self-driving cars, I'd have said "sure, eventually." Well, eventually is now. We've watched AI computing migrate from comfortable cloud servers to the messy reality of edge devices, and it's been quite a ride.

The thing is, once you move AI out of climate-controlled data centers and into the real world—factories, streets, vehicles—everything changes. Suddenly, your biggest headache isn't the AI algorithm or the processing power. It's the humble connector that's supposed to keep everything talking to each other while getting hammered by vibration, temperature swings, moisture, and dust.

This isn't just an engineering puzzle. It's become a make-or-break factor for entire product lines: how do you keep high-speed connections stable when Mother Nature is doing her best to kill them?

Why This Matters Right Now

The market numbers are pretty eye-opening. MarketsandMarkets thinks the edge AI space will grow 23% annually, ballooning from $15.4 billion last year to $38.5 billion by 2029. But here's the kicker: IDC found that by 2026, three-quarters of enterprise data processing will happen at the edge, not in some distant cloud.

What's driving this shift? Simple—latency kills. When a self-driving car has 10 milliseconds to decide whether to brake, or a factory robot needs to adjust its grip in real-time, a few hundred milliseconds of cloud delay might as well be an eternity.

The catch? Edge devices end up in the worst possible places for delicate electronics: parking lots, factory floors, moving vehicles. These environments will test connectors in ways that cubicle-dwelling servers never dreamed of.

Where the Rubber Meets the Road

Take automotive. Level 3 and 4 autonomous vehicles went from needing 3-5 AI modules three years ago to 15-20 today. Each one needs serious bandwidth, pushing total vehicle data demands close to 25 Gbps. That's a lot of data flying around in an environment that's constantly shaking, heating up, cooling down, and generally being hostile to electronics.

Industry isn't much friendlier. ABI Research found that 35% of industrial equipment now has edge AI baked in, with expectations to hit 60% in three years. These aren't pampered office machines—they're running in environments full of dust, oil, vibration, and workers who don't always treat electronics gently.

Smart cities are jumping on the bandwagon too. Over 1,000 cities worldwide are rolling out smart city projects, with 8 out of 10 using edge AI. That means thousands of AI processors sitting outside, dealing with weather, vandalism, and whatever else urban environments can throw at them.

The Real-World Problem: It's Always the Connector

I can't count how many times I've sat in meetings where someone says, "The AI is working perfectly, but..." and the next word is always "connector." It's not that connectors are rocket science—they're actually pretty straightforward. The problem is they fail way too often when you put them somewhere unpleasant.

Here's a scenario that plays out more often than anyone likes to admit: A factory spends millions on an AI quality control system. Everything looks great in testing. Three months into production, vibration works a connector loose, and the entire line shuts down. Or take outdoor surveillance cameras—they run fine for a year, then water gets into a connector because the weatherproofing degraded, and suddenly you've got expensive paperweights.

In our experience, connector problems account for 30-40% of all system failures in harsh environments. That's not a rounding error—that's a business problem.

The Sneaky Failures Are the Worst

Most connector failures aren't dramatic. They don't just stop working and flash a big red error message. Instead, they develop weird intermittent problems that drive engineering teams crazy.

Picture this: Your AI system seems fine, but occasionally it gets corrupted image data or sensor readings that jump around for no apparent reason. Your team spends weeks diving into software bugs, algorithm tweaks, and hardware diagnostics. Eventually, someone discovers that a perfectly normal-looking connector is having microscopic connection issues.

The diagnosis costs alone often run 20-30 times what the connector cost in the first place. When this happens in deployed systems, you're looking at field service calls, downtime, and customers questioning whether your product is reliable.

There's an old saying in the business: "Don't shop on price—shop on total cost of ownership." A connector that costs 20% more but runs trouble-free for five years beats a cheap one that might leave you scrambling any day of the week.

Four Technical Bottlenecks

.png)

.png)

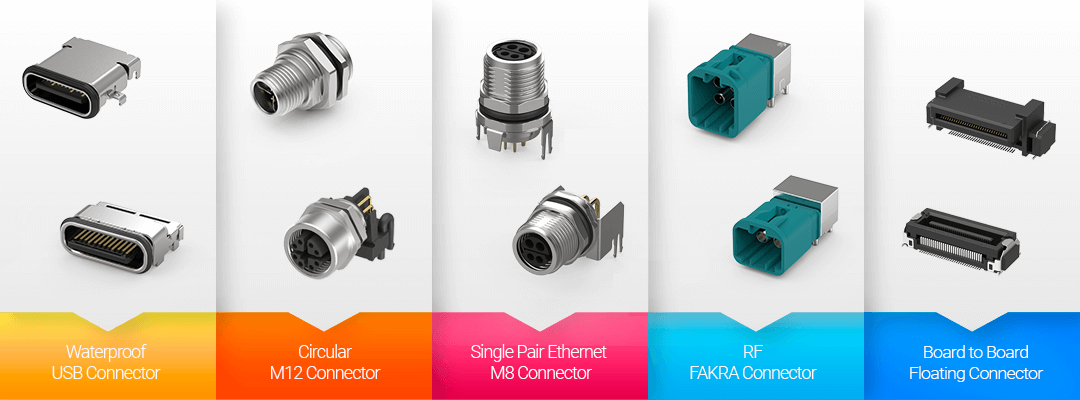

Product Selection Strategy: Comprehensive Connectivity from External to Internal

In edge AI design, connector selection should be divided into two major categories—external I/O interfaces and internal high-speed interconnects—each corresponding to different functional and environmental resistance requirements. Below we explore the core technical characteristics and applicable scenarios for each category.

External I/O Ruggedized Connectivity Solutions

External I/O ruggedized connectivity encompasses all connector types that directly interface with external environments and interact with external devices or systems, including M12 connectors common in industrial automation, waterproof USB Type-C for outdoor applications, and FAKRA/Mini-FAKRA RF interfaces dedicated to automotive communications. While FAKRA/Mini-FAKRA technically classify as high-frequency RF connectors, in practical applications they're typically installed on vehicle exteriors or system edges as critical interfaces between external antennas, cameras, and host modules, thus considered part of external I/O ruggedized connectivity.

- M12 Ruggedized: Feature IP67/IP68 protection ratings, quick-lock or threaded designs, and can withstand continuous vibration and impact. Ideal for industrial automation and outdoor edge AI.

- Waterproof USB Type-C: Achieve IP67/IP68 waterproof standards, supporting high-speed data transmission and power supply. Suitable for AI vision systems and data backup.

- FAKRA/Mini-FAKRA: Support up to 6 GHz RF transmission with low insertion loss, complying with ISO 20860 and USCAR standards. Perfect for automotive AI and radar communications.

- Single Pair Ethernet (SPE): Transmits data and power (PoDL) through a single twisted pair, simplifying wiring. Best for smart factories and sensor networks.

Internal High-Speed Interconnect Core Technology

Within systems, floating Board-to-Board connectors play critical roles connecting different computing modules. These connectors support PCIe 3.0 standards, providing up to 8 GT/s transmission rates while offering ±0.5 mm floating compensation capability.

- Floating Board-to-Board: Support PCIe 3.0 with 8 GT/s rates and ±0.5 mm compensation, operating from -40°C to +105°C. Ideal for embedded systems and automotive computers.

Power and Data Integration Transmission

Modern edge AI systems have growing power demands, leading to Power over Ethernet Plus Plus (PoE++) and Power over Data Line (PoDL) technologies.

- PoE++: Provides up to 90W of power through standard network cables while maintaining gigabit-level data transmission. Suits high-power AI cameras and edge platforms.

- PoDL: Offers up to 50W of power through single twisted pairs with 10 Mbps to 1 Gbps data transmission. Ideal for remote sensing and monitoring nodes.

Edge AI Connectivity Technology Selection Reference Table

| Application Type | Connection Technology | Key Characteristics | Applicable Scenarios |

|---|---|---|---|

| External I/O Ruggedized | M12 Ruggedized | IP67/IP68, shock/vibration resistance | Industrial automation, outdoor edge AI |

| External I/O Ruggedized | Waterproof USB-C | IP67/IP68, high-speed transmission with power | AI vision systems, data backup |

| External I/O Ruggedized | FAKRA Series | 6 GHz high-frequency, automotive standards | Automotive AI, radar communications |

| External I/O Ruggedized | SPE | PoDL power, simplified wiring | Smart factories, sensor networks |

| Internal High-Speed Interconnect | Floating Board-to-Board | PCIe 3.0, ±0.5mm compensation | Embedded systems, automotive computers |

| Power Data Integration | PoE++ | 90W power, gigabit transmission | AI cameras, edge platforms |

| Power Data Integration | PoDL | 50W power, single-line transmission | Remote sensing, monitoring nodes |

Critical Design Considerations

- Environmental Adaptability: Must pass vibration, shock, thermal cycling, and salt spray environmental tests. Support -40°C to +105°C wide temperature operation and meet IP67/IP68 protection ratings.

- High-Speed Transmission Capability: RF frequency support above 6 GHz, high-speed interconnects supporting PCIe 3.0 (8 GT/s) or higher, maintaining signal integrity at high frequencies.

- Modular and Standardized Design: Comply with ISO, USCAR, IEC international standards. Interchangeable interface structures for convenient maintenance and upgrades, supporting hot-swapping and real-time diagnostics.

- Flexible Integration: Balance full-chain connectivity between external sensors and internal computing modules. Support integrated transmission of data, power, and control signals, with scalability for future upgrades.

Application Scenarios

Autonomous Vehicle AI Platforms

High-speed cameras and radar connect to computing hosts through FAKRA/Mini-FAKRA and floating Board-to-Board interconnects, with PoE++ powering edge processing units. The entire system must withstand -40°C to +85°C automotive temperature variations while maintaining millisecond-level sensor fusion response times.

Smart City Surveillance

Outdoor AI cameras connect through waterproof USB Type-C or M12 interfaces, supporting high-speed video transmission and long-distance PoE power supply. Systems must pass IP67 protection certification and possess remote diagnostic and maintenance capabilities.

Industrial Inspection Systems

Internal modules use floating Board-to-Board, external I/O uses SPE or M12, ensuring high-speed data flow and durability. Systems must comply with Industry 4.0 standards, supporting predictive maintenance and real-time quality control.

Technical Development Trends and Future Outlook

Emerging Technology Trends

- 5G/6G Integration: Next-generation edge AI will deeply integrate 5G/6G communication capabilities, requiring connectors to support millimeter wave bands and ultra-high-speed data transmission.

- Optical-Electronic Hybrid Connectivity: As AI chip computing density rises, hybrid transmission of optical fiber and electronic signals will become standard for high-end applications.

- Smart Connectors: Connectors with self-diagnostic, predictive maintenance, and remote monitoring capabilities will become widespread.

Standardization Development

IEEE 802.3 standards continue evolving, with Single Pair Ethernet power transmission capability increasing from current 50W to over 100W. ISO 20860 automotive connectivity standards will also expand to support higher bandwidth AI application requirements.

Key Conclusions and Recommendations

Deploying edge AI in harsh environments requires not only powerful computing platforms but also critical connector selection for system success. Through comprehensive solutions targeting external I/O, waterproofing and high-speed transmission, and internal high-speed interconnects, design teams can balance performance, reliability, and maintenance convenience.

Core Recommendations

- Layered Design Strategy: Distinguish between external sensing and internal computing connectivity requirements, adopting differentiated product selection strategies.

- Standards-First Approach: Prioritize connectivity solutions complying with international standards, ensuring long-term supply chain stability and technology upgrade paths.

- System-Level Validation: Introduce comprehensive environmental testing and reliability verification during product design phases to reduce mass production risks.

- Ecosystem Integration: Select suppliers with complete supporting solutions (cables, tools, technical support) to accelerate time-to-market.

As edge AI technology continues evolving, connectivity solutions will transform from passive signal transmission tools into active system health management and performance optimization platforms, meeting next-generation AI systems' stringent stable connectivity demands.