When selecting the correct pogo pins for your project, understanding key factors like size, material, plating, and spring force is essential to ensure optimal device performance. Each element will affect how well the pogo pins will function in terms of current capacity, durability, and connection reliability. This guide will walk you through the critical considerations when choosing pogo pins and help you navigate the process of selecting the best manufacturer.

Tips to Choose the Right Pogo Pins

Choosing the correct pogo pins for your project can significantly affect your device's performance, durability, and efficiency. By carefully analyzing the following factors, you can ensure that your pogo pins provide optimal performance and longevity tailored to your specific application.

Size

Pogo pins range in diameter, typically from 0.5 mm to 2.0 mm. Smaller pins (0.5-0.8 mm) are best suited for compact, high-density PCBs, while larger pins (1.0-2.0 mm) are ideal for applications requiring higher current, as larger pins generally allow for greater current capacity. For example, a 2.0 mm pin can handle up to 5-6 amps of current, whereas smaller 0.5 mm pins may handle less than 1 amp.

Material

Pogo pins are commonly made from beryllium copper, phosphor bronze, and stainless steel. Beryllium copper is favored for its excellent conductivity (up to 50% IACS - International Annealed Copper Standard) and corrosion resistance. Phosphor bronze offers slightly lower conductivity but is more affordable, while stainless steel is highly durable and ideal for high-temperature applications (up to 250°C).

Plating Material

Gold plating (0.5-1.0 microns thick) is standard for pogo pins due to its superior conductivity and corrosion resistance. A thickness of at least 0.5 microns is recommended for applications involving frequent mating cycles (up to 100,000 cycles). Nickel plating, though less expensive, is less resistant to corrosion and wear, making it suitable for applications with lower cycle counts or less harsh environments.

Spring Force

Spring force, measured in grams, directly impacts the connection reliability. Standard pogo pins offer spring forces ranging from 10-60 grams. For applications requiring consistent contact through surface oxidation or debris, higher spring forces (30-60 grams) are ideal. However, too much force can damage delicate surfaces, so a force between 10-30 grams is more appropriate for standard electronics.

Mounting Method

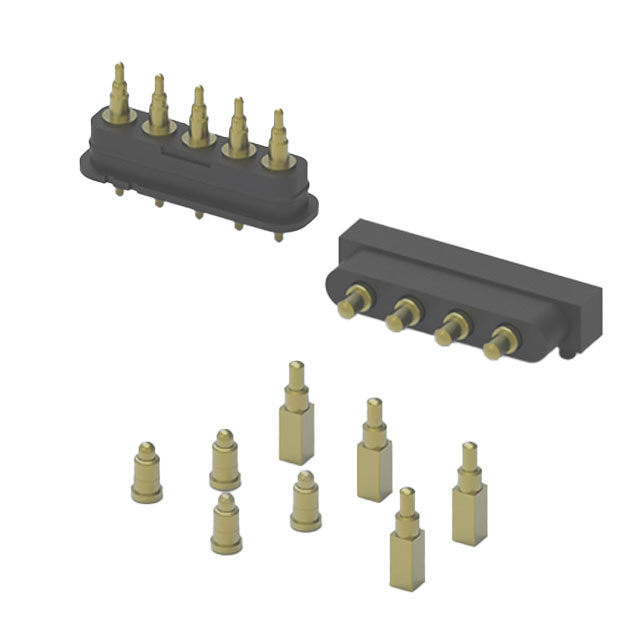

Pogo pins come in surface-mount (SMD), through-hole, or press-fit designs. SMD pogo pins are compact and save space, making them ideal for densely packed boards, while through-hole pins offer more robust mechanical support. Press-fit options are advantageous when soldering is not desired, and they typically provide a reliable connection in high-vibration environments.

Current Rating

The current rating of pogo pins depends on both size and material. A standard 1.0 mm gold-plated pogo pin typically supports currents of 2-3 amps, while larger 2.0 mm pins can handle up to 6 amps. Be sure to match the pin's current rating to your application's needs to prevent overheating or connection failure.

How to Choose the Suitable Pogo Pin Manufacturer

Choosing the proper pogo pin manufacturer is equally vital to ensuring the success and longevity of your electronic projects.

Quality

High-quality pogo pins ensure long-lasting performance, especially in demanding applications. Ensure the manufacturer meets industry certifications like ISO 9001, which guarantees strict quality control processes for reliable electrical contact and durability over thousands of cycles.

Customization

Your project may require specific pin configurations or materials. A good manufacturer will offer customization options, such as adjusting pin sizes, spring forces, and plating materials like gold or nickel to suit your technical needs.

Cost

While staying within budget is essential, ensure that cost-efficiency does not come at the expense of quality. Compare pricing structures to find a manufacturer that offers competitive rates while maintaining high standards in materials and manufacturing processes.

Lead Time

Time-to-market is crucial in many industries. Choose a manufacturer with a robust supply chain and the ability to deliver products within your project timeline without compromising quality.

Technical Support

Strong technical support is crucial if you need guidance in product selection or troubleshooting after installation. Look for manufacturers with a knowledgeable team that can provide timely assistance and problem-solving during the development and post-sales phases.

Choose ATTEND as Your Trusted Partner for Pogo Pins

Pogo pin connectors are reshaping the modern electronics industry with their multifunctionality, customization capabilities, and advanced features in areas such as magnetic charging and waterproofing.

Choose ATTEND as your trusted partner for high-quality pogo pins. With a strong focus on customization, we design solutions that optimize performance across various industries, including electronics, fitness, and healthcare. We provide cost-effective options without sacrificing durability or reliability.

Our efficient lead times ensure timely delivery, keeping your project on track, while their expert technical support team is available to guide you through product selection and troubleshooting. For innovative solutions like magnetic charging and waterproof designs, ATTEND is the ideal choice for dependable Pogo pin connectors.

Read More:

➤ Guide for M.2 SSD Types, Protocols, and Key Configurations

➤ PCB Connector Types, Functions, and Selection Tips

➤ Spring Loaded Pogo Pins & Connectors | ATTEND Technology

➤ M12 Connector | ATTEND Technology

➤ What is the M12 Connector: Code Types, Benefits, and More | ATTEND