ATTEND’s FAKRA connectors deliver high-performance RF connectivity for automotive and industrial applications. Designed to withstand vibration, temperature extremes, moisture, and dust, these connectors support critical communication systems while meeting ISO 20860-1/2, SAE/USCAR-2, and USCAR-17 standards.

With a comprehensive range of FAKRA connector types, cable assemblies, and color-coded options, ATTEND ensures secure, consistent signal transmission across diverse applications. Browse our FAKRA selections below to find the right solution for your connectivity needs.

In addition to our RF FAKRA connectors (228 FAKRA series and 230 Mini FAKRA series), ATTEND also offers 231 HSD series and 232 HS-MTP series for high-speed digital data applications, ensuring comprehensive connectivity solutions for modern automotive systems.

Series | Code | Port Count | Connector Types | Impedance | Frequency |

|---|---|---|---|---|---|

A, B, C, D, E, F, G, H, I, K, L, M, N, Z | 1x1 1x2 | Straight PCB through-hole receptacle | 50 Ω | DC TO 6 GHz | |

Right-angle mid-mount PCB through-hole receptacle | |||||

A, B, C, D, E, F, G, H, J, K, N, Z | 1x1 1x2 2x2 | Straight PCB through-hole receptacle | 50 Ω | DC TO 15 GHz | |

Right-angle PCB through-hole receptacle | |||||

A, B, C, D, E, F, Z | 1x1 | Straight PCB through-hole receptacle | 100 Ω | DC TO 2 GHz | |

Right-angle PCB through-hole receptacle | |||||

A, B, C, D, E, F, G, H, J, K, L, M, O, Z | 1x1 1x2 2x2 2x3 | Straight PCB through-hole receptacle | 100 Ω | DC TO 20 GHz | |

| Right-angle PCB through-hole receptacle |

What is a FAKRA Connector?

FAKRA connectors are standardized coaxial connectors. The acronym “FAKRA” stands for "Fachkreis Automobil," meaning "Automotive Expert Group" in German. They are widely adopted for vehicle connectivity, relying on a simple push-on mechanism to route high-frequency RF (Radio Frequency) signals for GPS, satellite radio, cellular communication, and ADAS (Advanced Driver-Assistance Systems) cameras.

FAKRA Connector Design and Manufacturing Evolution

FAKRA connectors have continuously evolved to meet the changing needs of the automotive industry, progressing from early in-vehicle systems to today’s advanced autonomous applications. Each stage of improvement has focused on enhancing RF performance, durability, and production efficiency, while maintaining compliance with global standards such as USCAR-17, USCAR-18, and DIN 72594-1.

The earliest designs used machined SMB-based contacts, delivering stable connectivity for GPS, satellite radio, and in-vehicle infotainment. Later developments introduced die-cast bodies and pre-assembled housings, lowering installation costs and improving efficiency. As demands for higher durability grew, stamped contacts and closed-entry interfaces were added for greater robustness in high-speed signal applications such as LVDS (low-voltage differential signaling) surround-view camera systems.

The most recent advancements emphasize high-speed automated production with stamped components and modular housings, enabling scalability, low latency, and high signal integrity for V2X (Vehicle-to-Everything) applications, especially safety-critical technologies like blind-spot monitoring, emergency alerts, and autonomous driving.

| FAKRA Advancement Stage | Design & Manufacturing Features | Tooling Requirements | Production Scale | Compliance Standards |

|---|---|---|---|---|

| Foundation Advancement | Machined SMB-based body and contacts; plastic housing; easy assembly | Manual Tooling | Low Volume | USCAR-17, USCAR-18, DIN 72594-1 |

| Cost-Optimized Advancement | Die-cast body; pre-assembled housing; reduced installation costs | Manual Tooling | Low Volume | USCAR-17, USCAR-18, DIN 72594-1 |

| Efficiency Advancement | Die-cast body; stamped contacts; optimized design for faster assembly | Semi-Automated/Automated Tooling | High Volume | USCAR-17, USCAR-18, DIN 72594-1 |

| Durability Advancement | Die-cast body; stamped contacts; closed-entry interface for durability | Semi-Automated/Automated Tooling | High Volume | USCAR-17, USCAR-18, DIN 72594-1 |

| V2X Advancement | Stamped body and contacts; modular housing; supports high-speed automated production for advanced safety systems | Fully Automated Tooling | High Volume | USCAR-17, USCAR-18, DIN 72594-1, 6Q0.90.961D/E |

By keeping up with these developments, ATTEND offers the latest FAKRA connector models built to meet these advanced requirements while remaining backward-compatible for legacy systems, making them a trusted choice for modern automotive and industrial connectivity.

FAKRA Connector Types Available

FAKRA Configuration

FAKRA connectors are available in various configurations to suit diverse connection needs within automotive and industrial systems:

-

Male (Plug) vs. Female (Jack): Male FAKRA connectors typically feature a center pin and are mounted on cables, while female FAKRA connectors have a center sleeve and are attached to devices, housings, or PCBs.

-

Straight vs. Right-Angle (R/A): Straight connectors allow the cable to extend directly from the connection point, making them ideal for inline connections in tight cable runs. In contrast, R/A connectors point at a 90-degree angle from the cable to optimize cable routing and strain relief, making them common in dashboard-mounted modules or crowded PCB layouts.

-

Cable Assembly vs. Individual Connector: FAKRA connectors can be purchased as pre-terminated FAKRA cable assemblies for ready-to-use solutions or as individual connectors for custom cable fabrication.

At ATTEND, we provide a wide range of FAKRA cable assemblies, including straight and right-angle, male and female, as well as single- or multi-port options, offering flexibility for diverse applications.

FAKRA Color Codes

FAKRA connectors use a standardized color-coding system to differentiate their functions within a vehicle’s RF and communication systems, as seen in the table below.

Each color is paired with a specific mechanical keying feature to ensure it can only be plugged into the designated port. This helps to prevent mismating while simplifying installation, maintenance, and troubleshooting. These color codes are also consistent across multiple manufacturers, allowing for interoperability.

ATTEND offers all standard FAKRA color code options, allowing engineers and integrators to select the right connector for any system:

| Code | RAL No. / Color | Europe Application | USCAR Application | |

|---|---|---|---|---|

| A | 9005 Jet Black | Radio without phantom supply | ||

| B | 9001 Cream | Radio with phantom supply | ||

| C | 5005 Signal Blue | GPS / Navigation | ||

| D | 4004 Claret Violet | GSM | ||

| E | 6002 Leaf Green | TV / SDARS Terrestrial | ||

| F | 8011 Nut Brown | TV / SDARS Terrestrial / Camera | ||

| G | 7031 Blue Gray | Remote Keyless Entry | SDARS Terrestrial | |

| H | 4003 Heather Violet | GPS / Navigation | ||

| I | 1001 Beige | Remote | Bluetooth / VP | |

| K | 1027 Curry | Diversity radio | SDARS Satellite | |

| L | 3002 Carmine Red | Undefined | VP | |

| M | 2003 Pastel Orange | Undefined | RKE / TPMS | |

| N | 6019 Pastel Green | Undefined | DSRC / VP | |

| Z | 5021 Water Blue | Universal (Neutral) | ||

ATTEND’s FAKRA Connector Features and Benefits

-

Secure Locking Mechanism: Our FAKRA connectors have a push-on coupling with a tactile and audible click that confirms a proper connection, resisting vibration and shock while eliminating uncertainty during installation.

-

Smooth Signal Transfer: The FAKRA connectors support reliable electrical performance from DC up to 6 GHz, ensuring seamless connectivity for modern applications such as high-resolution cameras, infotainment systems, and advanced driver-assistance systems (ADAS).

-

Stable Electrical Performance: These connectors deliver stable performance with 50 Ω impedance, 1.0 A max current, and 335 Vrms continuous voltage, providing signal integrity and power stability in demanding automotive environments.

-

Durability and Environmental Resistance: Designed with rugged plastic housing, these connectors can achieve at least 25 mating cycles and support operating temperatures from −40°C to +105°C. We even offer IP67 and IP69K options for maximum protection against moisture, dust, and high-pressure wash-downs.

-

Standard Compliance and Coding: Our FAKRA connectors fully comply with ISO 20860-1/2, SAE/USCAR-2, and USCAR-17 standards, while offering 13 color-coded variants plus 1 neutral option to prevent mismating and simplify system integration.

Applications of Our FAKRA Connectors

ATTEND’s FAKRA connectors support a wide range of wireless technologies, including Bluetooth, Wi-Fi, and Zigbee, making them versatile solutions for both automotive and industrial communication systems. Common applications include:

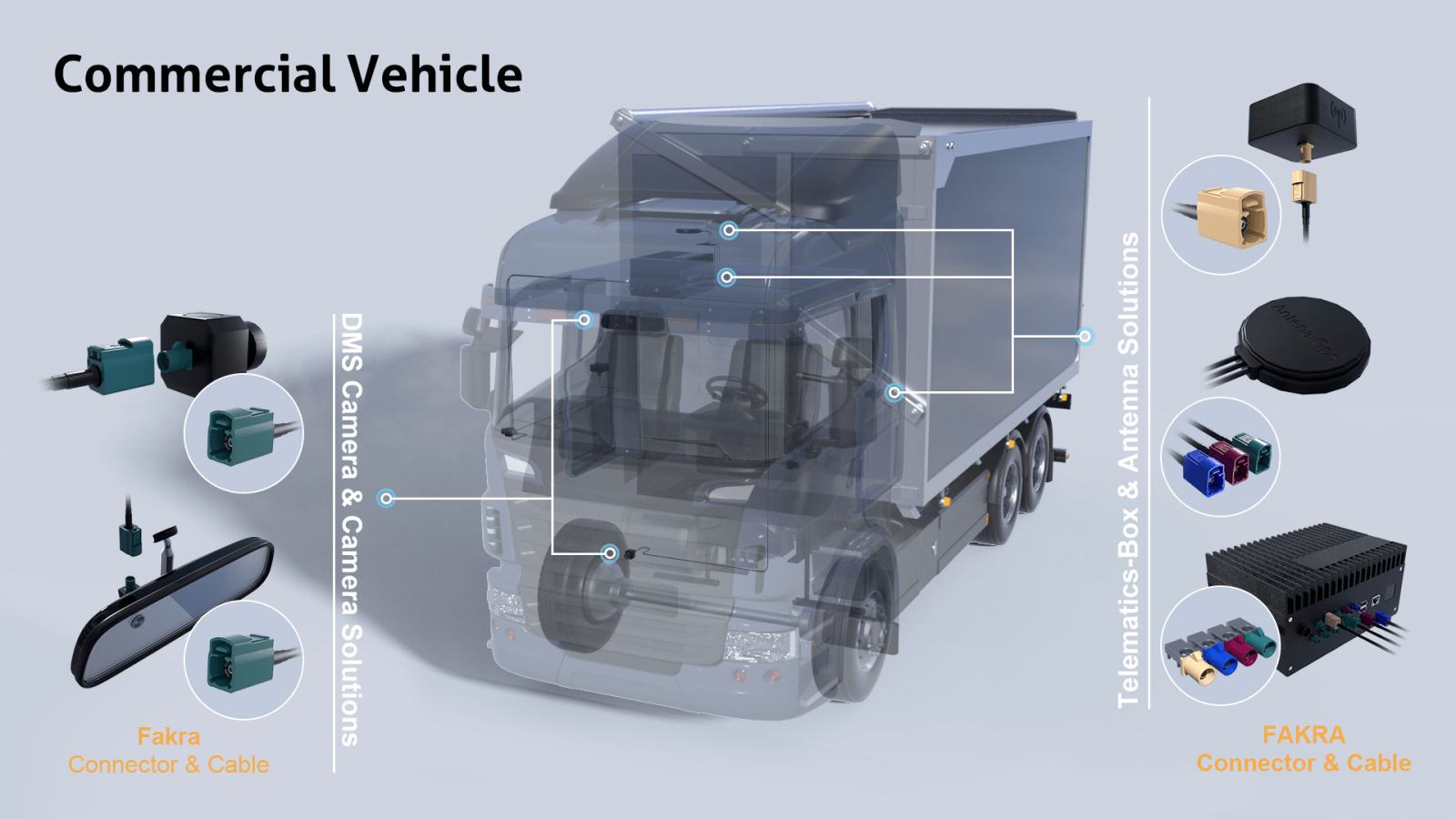

Automotive & Transportation

- Automotive Telematics & Infotainment Systems: FAKRA connectors enable high-quality connections for GPS, satellite radio, and in-vehicle entertainment, ensuring seamless navigation and media streaming. They are also used in hands-free Bluetooth systems and Wi-Fi hotspots in connected cars.

- Advanced Driver Assistance Systems (ADAS): The connectors provide dependable RF connections for cameras, radar, and lidar sensors, which are critical for applications like lane departure warnings, parking assistance, and collision avoidance.

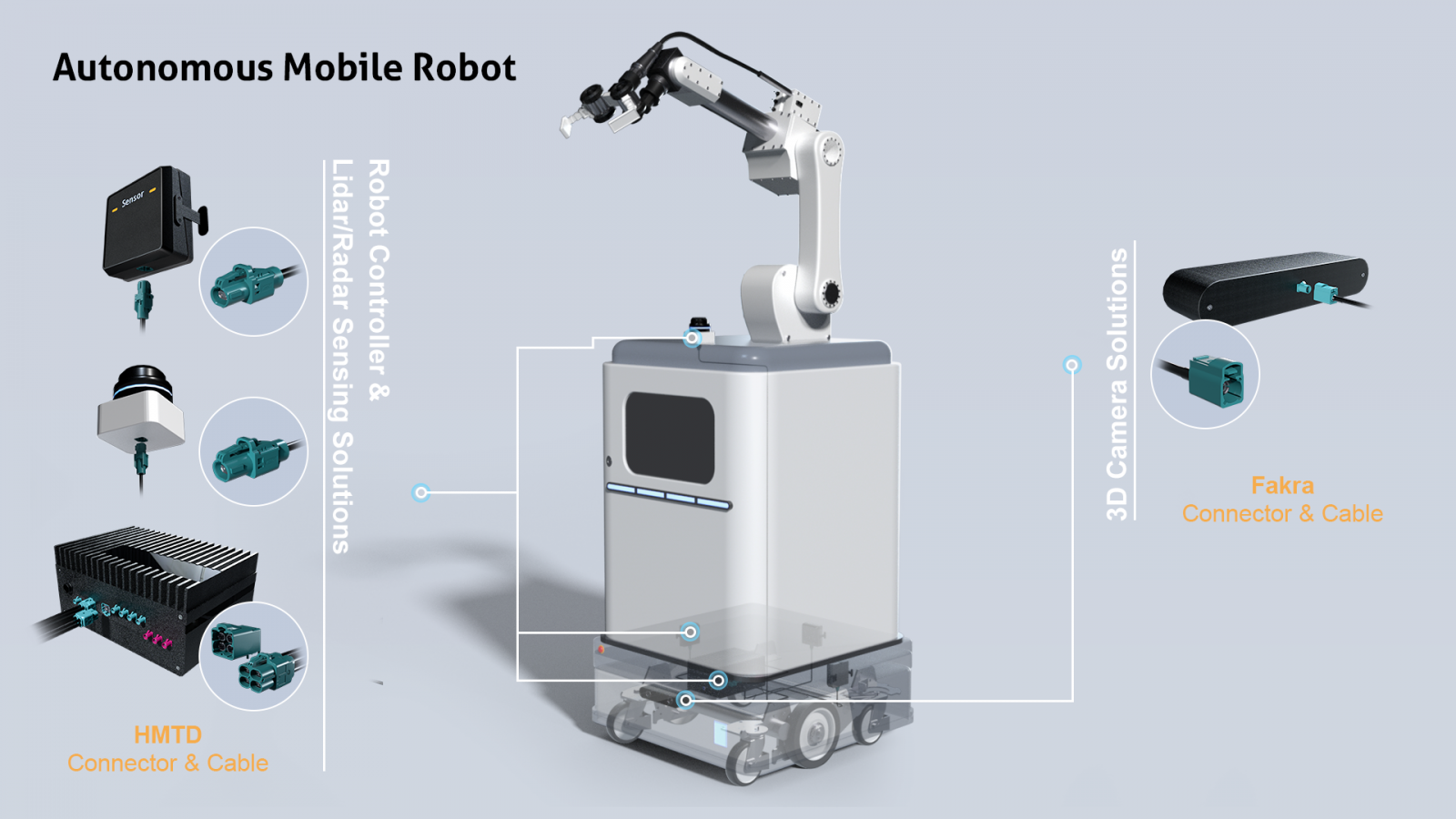

Robotics & Autonomous

Robotics & Autonomous

AGVs / AMRs / Robotics: FAKRA supports connectivity for lidar, radar, and 3D camera modules in autonomous guided vehicles and mobile robots, enabling accurate navigation and obstacle detection Agricultural & Heavy-Duty

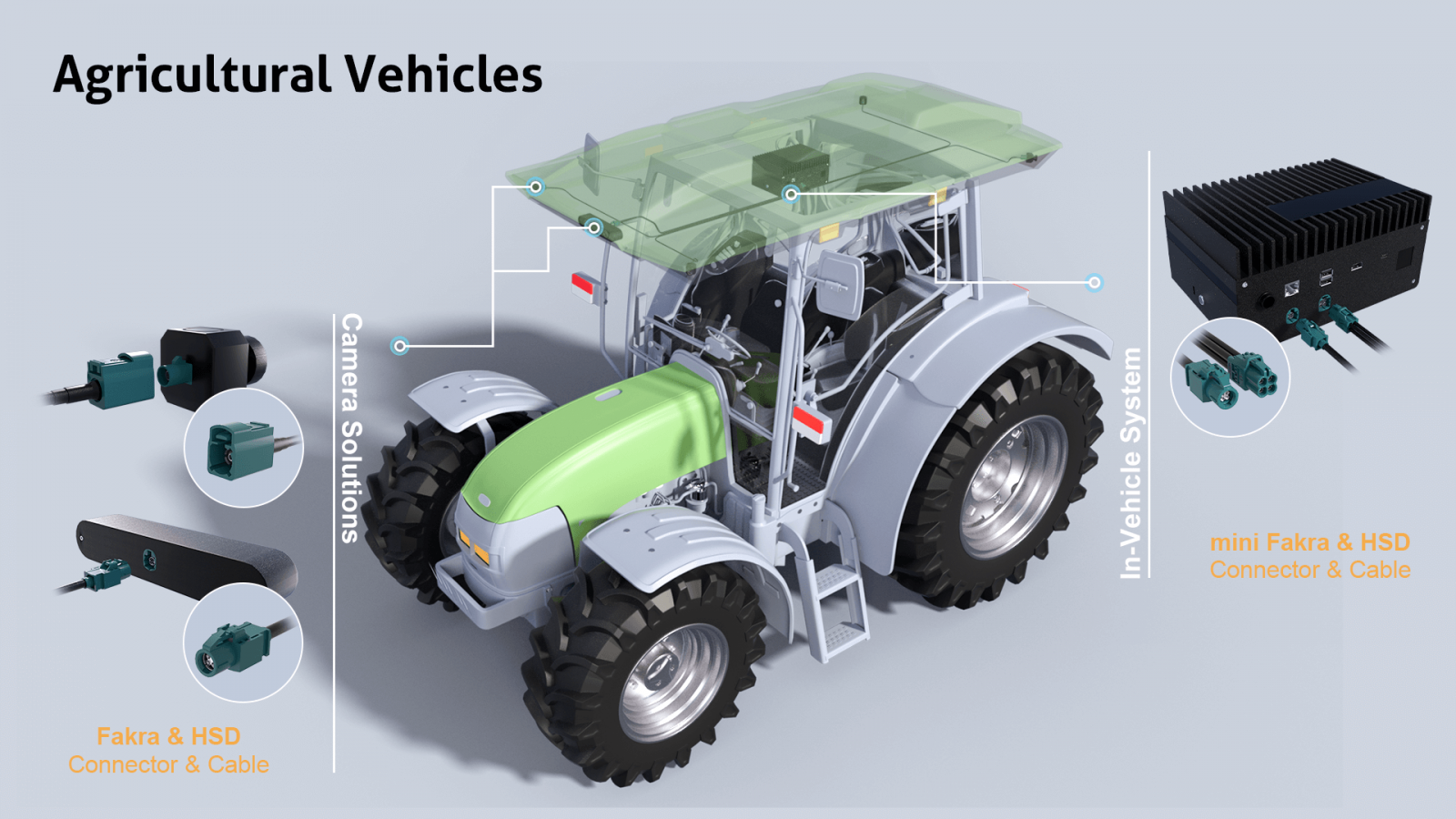

Agricultural & Heavy-Duty

Agricultural & Transportation Machinery: Used in vehicle-mounted cameras, telematics units, and antenna systems, FAKRA connectors improve operational safety and efficiency in tractors, harvesters, and heavy-duty trucks..png)

Industrial & Communication Infrastructure

- Industrial Wireless Communication: Widely applied in IIoT (Industrial Internet of Things) systems, FAKRA ensures stable data transfer for factory automation, predictive maintenance, and remote monitoring.

- Telecommunication: FAKRA connectors also enhance wireless routers, gateways, and smart devices, ensuring durable and scalable RF performance for communication networks.

FAKRA Connector FAQs

Are FAKRA connectors the same as SMB?

No, FAKRA connectors are not the same as SMB connectors. FAKRA connectors are derived from SMB connectors but include a plastic housing with color coding and a locking mechanism. This design improves durability, prevents mismating, and ensures secure connections in high-vibration automotive environments.

What is the difference between FAKRA, SMA, and HSD connectors?

FAKRA, SMA, and HSD connectors all support RF and data transmission, but are designed for different applications and environments. FAKRA is optimized for secure automotive RF connections, SMA is preferred for telecom and testing for high-frequency precision, while HSD is more common in high-speed digital data in vehicles.

| Connector Type | FAKRA | SMA | HSD |

|---|---|---|---|

| Primary Use | Automotive RF Signals (GPS, Radio, Cellular) | General RF/Microwave | High-Speed Digital Data (LVDS, Ethernet) |

| Mating Mechanism | Push-On (with audible click) | Screw-Threaded | Push-Pull |

| Housing | Plastic with color coding | Metal | Shielded |

| Frequency / Data Capability | Up to 6 GHz and around 8 Gbps | Up to 18 GHz (higher in precision versions) | Multi-Gbps digital data |

| Key Advantage | Secure, vibration-resistant, prevents mismating | High-frequency performance, compact size | Excellent signal integrity for high-speed applications |

What is the FAKRA standard?

The FAKRA standard defines the mechanical and electrical specifications of automotive RF connectors. Compliant with ISO 20860-1/2, DIN ISO 20860, and SAE/USCAR-18, it guarantees reliable, standardized connectivity for global vehicle communication, infotainment, and safety systems.

What is the FAKRA Z connector for?

The neutral-coded FAKRA Z connector (water blue color) is a versatile universal RF interface widely adopted in automotive camera and machine-vision applications, including surround-view systems, parking cameras, and ADAS sensors. Beyond its original low-frequency signal applications, such as AM/FM radio antennas in vehicles, the FAKRA Z connector’s neutral coding provides flexibility for OEM-specific implementations, universal testing, prototype connector use, as well as applications not covered by standard color-coded variants.

What are the common problems with the FAKRA connector?

Common FAKRA connector issues include:

- Loose Connections/Mismating: Occurs if the connector isn't fully seated or the locking mechanism fails due to vibration. To prevent this, make sure there is an audible "click" during installation, and use a torque wrench to tighten to the proper specification for a secure, long-lasting fit.

- Bent or Broken Pins: This is often a result of improper handling during assembly. Carefully inspect pins before mating and replace damaged connectors with new, reliable ones to restore electrical contact whenever necessary.

- Signal Degradation: Poor connection or insufficient shielding can lead to signal loss or interference. So, be sure to use well-shielded, high-quality connectors and ensure all components are routed away from strong electromagnetic sources.

What tools do I need to install ATTEND’s FAKRA connectors?

ATTEND's FAKRA cable assemblies are ready-to-use with the connector already attached and tested. Therefore, you do not need special crimping or stripping tools to install it.

Browse Our FAKRA Connector Solutions

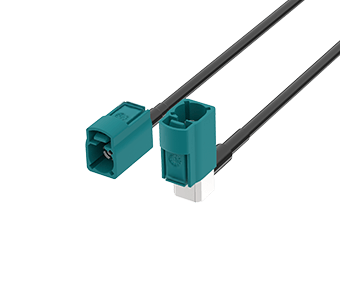

FR-1J1J-100Z02W

FR-1J1J-100Z02W FAKRA Jack STR to Jack R/A Cable, L=100CM, IP69K, Z

INQURY FR-1J1P-100Z01W

FR-1J1P-100Z01W FAKRA Jack to Plug STR Cable, L=100CM, IP69K, Z

INQURY FR-1J1J-100Z01W

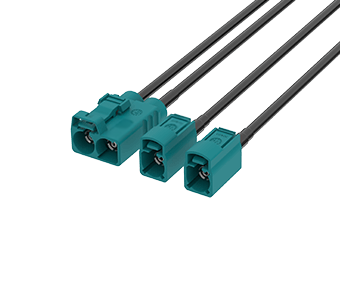

FR-1J1J-100Z01W FAKRA Jack(1x2) to Jack x2 Cable, L=100 CM

INQURY FR-1J2P-100X01

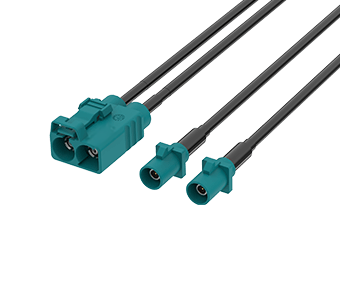

FR-1J2P-100X01 FAKRA Jack(1x2) to Plug x2 Cable, L=100 CM

INQURY FR-1J2J-100X01

FR-1J2J-100X01 FAKRA Jack(1x2) to Jack x2 Cable, L=100 CM

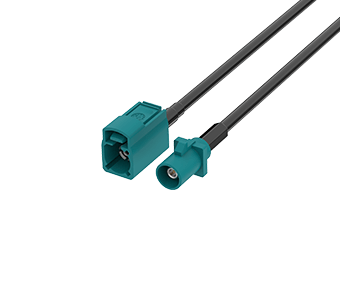

INQURY FR-1J1P-100X01

FR-1J1P-100X01 FAKRA Jack to Plug Straight Cable, L=100 CM

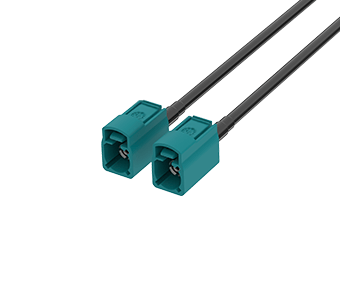

INQURY FR-1J1J-100X01

FR-1J1J-100X01 FAKRA Jack to Jack Straight Cable, L=100 CM

INQURY FR-1J1J-100X02

FR-1J1J-100X02 FAKRA Jack to Jack R/A Cable, L=100 CM

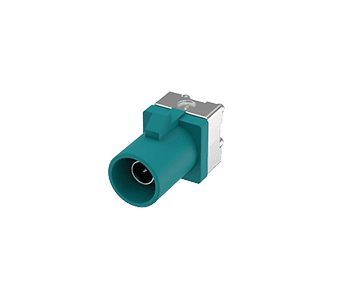

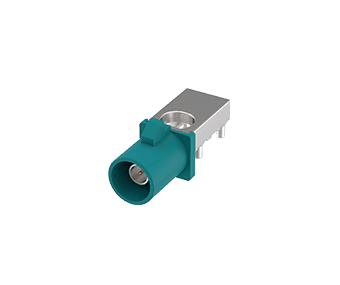

INQURY 228B-PXX00

228B-PXX00 FAKRA Plug, 1x2 Port, R/A, Mid Mount, Nose 12/6 O'clock

INQURY 228A-PSX00

228A-PSX00 FAKRA Plug, Vertical

INQURY 228A-PXX00

228A-PXX00