What are Pogo Pins?

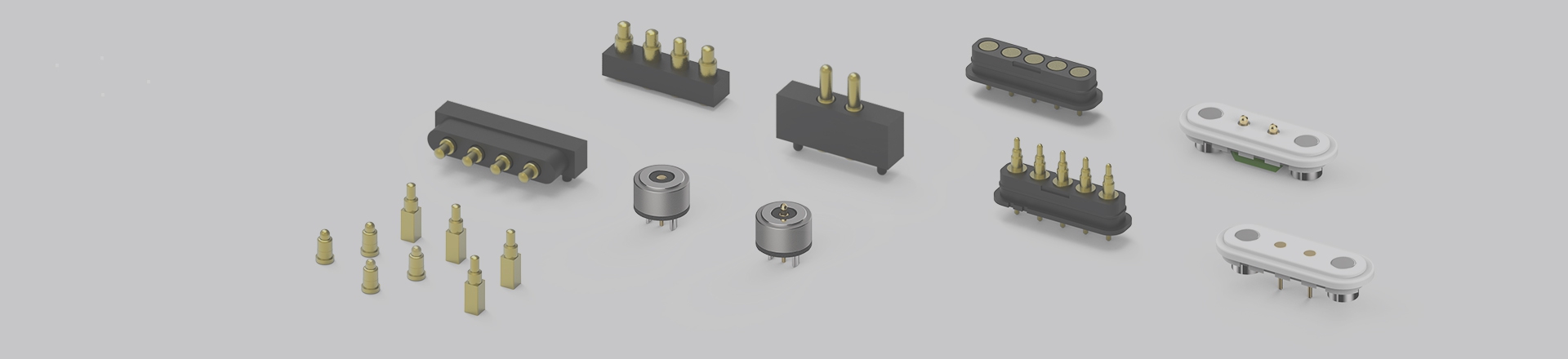

Pogo Pin Types Offered by ATTEND

ATTEND offers a comprehensive range of pogo pin types to satisfy your specific needs. We specialize in multi-pin connectors that efficiently handle complex circuitry and single-pin designs that provide focused connectivity for specialized tasks.

Beyond our standard options, we provide waterproof pogo pins connectors and magnetic pogo pin connectors for robust appications.

Here is a brief overview of our 303 series pogo pins:

| Series | Key Feature | Pin Count | Mounting Types | Working Height (mm) |

|---|---|---|---|---|

| 303A | Standard spring-loaded pin | Single | SMT | 2.6-6.8 |

| 303B | Standard spring-loaded pin | Multi-pin | SMT or Through-hole | 3.9-7.0 |

| 303C | Waterproof connector | Multi-pin | SMT or Through-hole | - |

| 303D | Magnetic connector | Multi-pin | SMT or Through-hole | 3.15-6.0 |

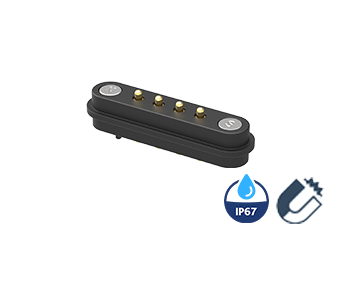

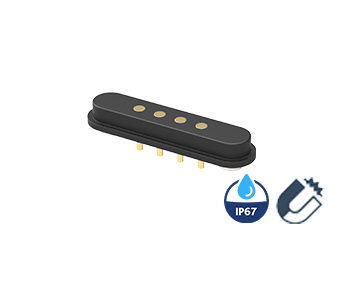

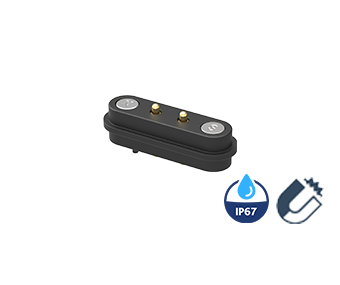

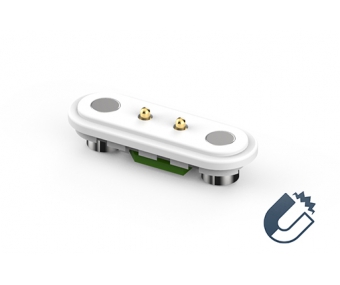

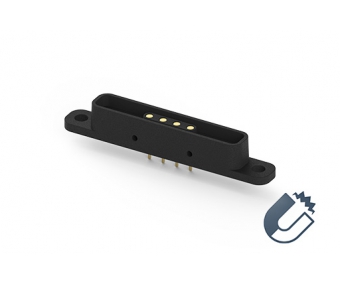

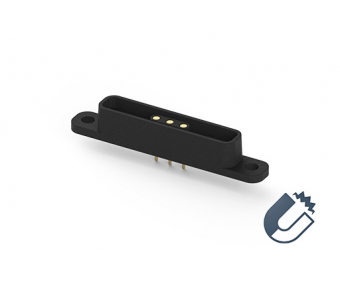

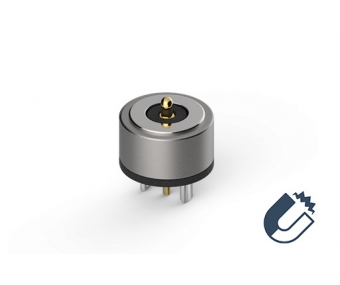

Magnetic Pogo Pin Connector

ATTEND’s magnetic pogo pin features male and female ends that automatically engage, enabling precise alignment. Their safe break-away mechanism will also prevent damage to the device when disconnecting.

Our magnetic pogo pin is particularly ideal for maintaining secure connections in applications involving constant movement or mechanical vibration, such as wearable devices, including smartwatches, smart glasses, fitness trackers, and medical monitors, as well as docking stations for portable devices, e-bikes, smart home devices, IoT equipment, and more.

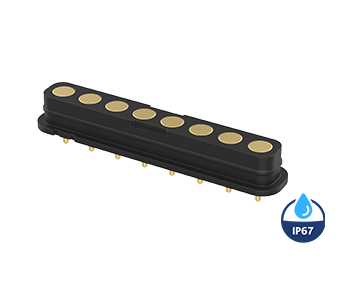

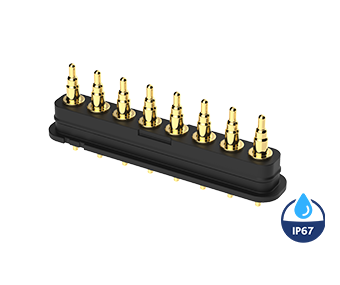

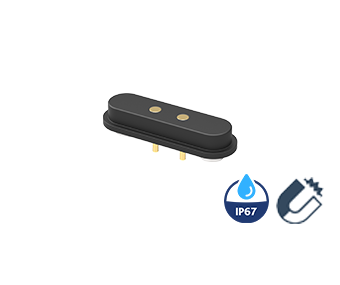

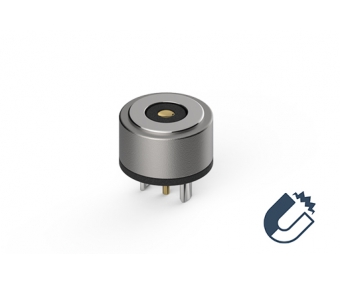

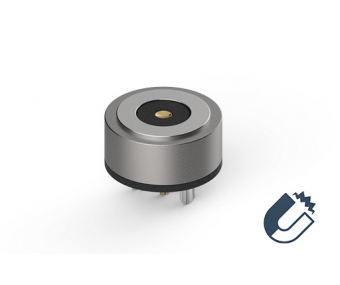

Waterproof Pogo Pin Connector

Our waterproof pogo pins are IP67-rated. This means on top of the magnetic features, these connectors have specialized seals that protect the components against dust and prevent liquid ingress when submerged.

As such, they can ensure reliable performance in harsh environments, making them ideal for outdoor electronics, marine equipment, and medical devices where exposure to debris or moisture is a concern.

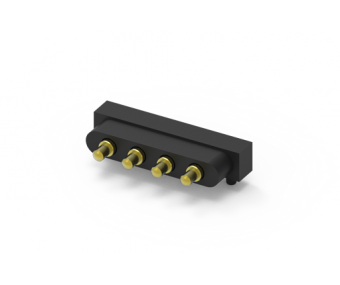

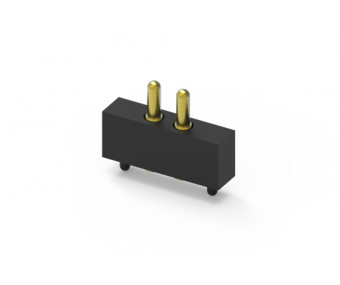

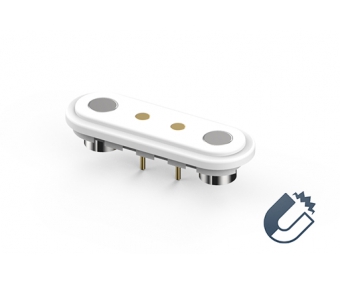

Multi-Pin Connector

ATTEND’s multi-pin pogo pin connectors combine multiple connections into a single, compact unit. This simplifies assembly, especially for complex circuits requiring simultaneous data and power transmission in docking stations, portable electronics, or test equipment.

We currently offer ready-for-order options with 2 to 4 pins in a single housing but you can also contact us to discuss custom solutions for your unique application.

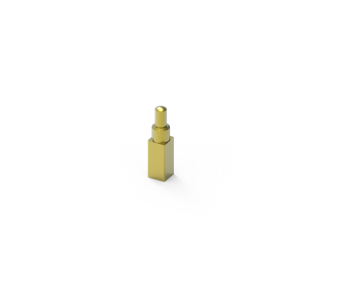

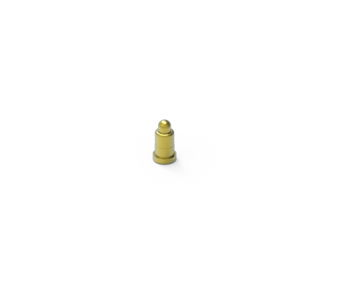

Single-Pin Connector

Designed as small, self-contained units, our single-pin connectors offer a precise and cost-effective solution for applications needing only one connection point, whether for miniature devices, charging contacts, or sensor connections.

If you need help with choosing from our comprehensive catalog, just click on the button below and let our expert provide strategic guidance to help you select the right pogo pin solution for your specific needs.

With over 20 years of experience in semiconductor and electronic components sales, Jaime is a seasoned professional well-versed in pogo pins, as well as connectors, power supplies, LEDs, memory, etc. Leveraging his deep understanding of the market, he has helped our clients grow within various industries in the USA, from networking to industrial machinery, medical, computing, military aviation, and more.

Why Choose ATTEND Pogo Pins?

With ATTEND as your partner, you can be confident in the quality, reliability, and performance of the pogo pins.

.png)

(2).png)

.png)

Excellent Mechanical Features

🧩 Compact and Space EfficientOur pogo pins are sleek and lightweight, with basic working heights of 2.6~7.5mm and diameters of 1.80~1.83mm for single-pin connectors. Some of our pogo pins also support board-to-board (B2B) connections, eliminating the need for wiring in space-constrained circuit boards.

🔩 Great Durability and Strength

Leveraging precision CNC machining, quality materials, and high-precision design, we create strong and long-lasting pogo pins that can withstand 10,000 to 50,000 mating cycles. If you need specialized applications, we offer simulation analysis to help you select the most suitable spring plunger and ensure durability.

⚡ Reliable Electrical Connectivity and Performance

Our pogo pins, rated at 1-3 amps, can deliver efficient performance without compromising safety. They maintain optimal contact pressure even under slight misalignments, offering stable electrical connections and enhanced shock resistance due to the wide spring force range exceeding 0.5N~1.5N. Their contact resistance is also minimized to around ≤20mΩ thanks to smooth, high-conductivity materials like gold-plated brass.

🌡️ Harsh Environment Tolerance

ATTEND uses durable materials like stainless steel and phosphor bronze with protective gold plating for superior resistance against moisture and corrosion. Our pogo pins endure temperatures from -40°C to +85°C, preventing deformation under extreme conditions and ensuring reliable connections in demanding applications.

Quality Material

- Pin (Plunger): Made from brass coated with gold or nickel for durability, corrosion resistance, hardness and excellent conductivity.

- Spring: Made from stainless steel as the material has strong resilience to ensure a consistent spring force over extended use. It also boasts resistance towards corrosion and high temperatures, while having non-magnetic properties to ensure smooth operation.

- Barrel: Commonly made from brass or phosphor bronze. Brass is a cost-effective option that is also valued for its good formability, which allows the creation of various barrel shapes; phosphor bronze, though more costly, offers a good balance of conductivity and formability, while providing superior corrosion resistance compared to brass.

- Housing: Made from Thermoplastic LCP (Liquid Crystal Polymer) PA6T that can withstand higher temperatures and many types of chemical, allowing it to maintain its shape under varying harsh conditions and mechanical stress better than traditional thermoplastics. This housing material also offers good insulating properties to prevent electrical shorts and ensure safe operation.

Success Stories

.jpg)

A Greener Meeting Experience Takes Flight with ATTEND's Pogo Pin Solution

A leading innovator in e-paper meeting room displays needed a more convenient and reliable charging solution for their growing product line. Traditional plugs were clunky and risked damaging ports, hindering both usability and device lifespan.ATTEND Pogo Pin Solution revolutionized charging for e-paper meeting room displays. It became user-friendly, efficient, and reliable. This innovative partnership not only streamlined the process but also extended device's lifespan, showcasing the company's commitment to progress.

.png)

Pogo Pins: The Tiny Connectors Powering Big Innovation

ATTEND Pogo pin connectors are revolutionizing device connections! Our compact design and reliable connections are ideal for board-to-board applications in sophisticated electronics. Customization options ensure optimal performance across diverse industries, from consumer electronics to medical devices. Innovation in magnetic charging simplifies usage, while advanced waterproofing opens doors for applications in outdoor, fitness, and healthcare sectors.

More Information About Pogo Pins

Pogo Pin Components

Barrel

Spring

Pin (Plunger)

Housing

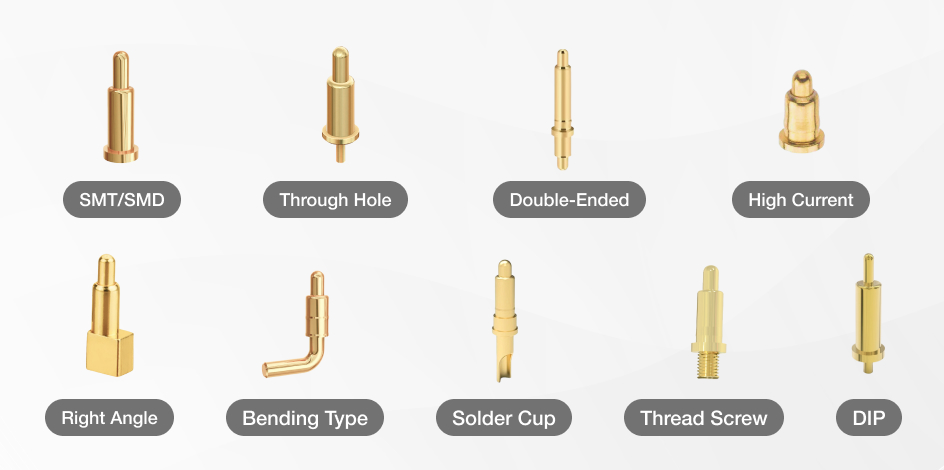

Mounting Types of Pogo Pin

ATTEND currently offers SMT pogo pins, through-hole mounting pogo pins and DIP pogo pins, catering to multiple applications.

SMT (Surface Mount Technology)

These pogo pins are soldered directly onto the PCB surface, and offer a compact, space-saving design, which is suited for modern, miniaturized electronics. Plus, SMT facilitates faster and more automated assembly processes, leading to quicker production times.

Through-Hole Mounting

Through-hole pogo pins have leads that pass through holes in the PCB and are soldered on the other side. This method provides a robust mechanical connection, ideal for applications requiring high durability and resistance to shock or vibration.

DIP (Dual In-Line Package)

DIP pogo pins have plug-in mechanisms, allowing them to be easily placed onto the PCB by hand before being soldered in place. It's also easier to inspect and rework compared to through-hole mounting, making it suitable for on-site maintenance. Though this mounting method is no longer common in modern devices, they are still highly compatible across multiple vendors.

Pogo Pin Application

Pogo pins offer diverse applications across various industries as they can create convenient yet robust electrical pathways. Common uses include:

-

Device Charging: Pogo pins ensure secure and efficient power transfer for portable devices such as smartphones, tablets, and handheld computers.

- Equipment Testing: Pogo pins are ideal interfaces for diagnostics and analysis because they offer a reliable and repeatable connection to the device under test (DUT), allowing engineers to obtain accurate readings.

- Signal Transmission: With low contact resistance, pogo pins can maintain a stable connection even at high frequencies. So, not only are they suitable for conventional memory connectors, but they can also withstand the high data transfer rates in IoT applications and POS terminals without major signal loss.

- Board-to-Board Connections: Due to the pogo pin’s compact design, it is often used for direct connections between internal printed circuit boards (PCBs) to save space.

How to Select the Best Pogo Pin Design for Your Needs?

You should carefully evaluate these factors to select a pogo pin that meets both performance and durability needs for your specific application:

-

Size and Format: Define the precise dimensions, including pin diameter, lead size, and pin shape (e.g., round, square). This ensures optimal mechanical fit within your device's spatial constraints.

-

Contact Material: The contact material should provide the optimal conductivity, mechanical strength, and compatibility with your application. Brass is usually the most popular option due to its excellent balance of performance and durability, making it ideal for the frequent compression and recovery cycles of pogo pins.

-

Contact Plating: Pogo pins often rely on plating to enhance conductivity, reduce contact resistance, and protect against corrosion. Common plating materials include gold and nickel.

-

Electrical Metrics: Assess the necessary current rating and target contact resistance to make sure the pogo pin can handle the electrical load efficiently without overheating or signal degradation.

-

Movement: Consider the plunger's working height, travel distance, and dimensional tolerances. This ensures reliable compression and consistent contact throughout the pin's movement range.

-

Physical Metrics: Determine the initial force required to make contact and the sustained force needed during compression. This ensures the pin's mechanical performance aligns with your application's operational demands.

-

Environmental Factors: Account for exposure to moisture, extreme temperatures, shock, vibration, or corrosive environments to ensure consistent performance under harsh conditions.

|

303D-L236F041

303D-L236F041 Machine Pin Magnetic, 4P H5.0, DIP, IP67

INQURY 303C-C3018-25-08

303C-C3018-25-08 Machine Pin Waterproof, 8P H3.0, 2.5mm, DIP, 30u", IP67

INQURY 303C-541219-25-08

303C-541219-25-08 Pogo Pin Waterproof, 8P H6.6, 2.5mm, DIP, 40u", IP67

INQURY 303A-C4418-000

303A-C4418-000 Machine Pin, Single pin, H=4.4mm, 10u''

INQURY 303A-753018-000

303A-753018-000 Pogo Pin, Single pin, H=7.50 mm, 10u''

INQURY 303A-441615-000

303A-441615-000 Pogo Pin, H6.0 Rectangle Body R/A SMT 5u''

INQURY 303A-250918-002

303A-250918-002 Pogo Pin, 1Pin T/L 3.4mm W/H 2.6mm

INQURY 303B-371318-254-04

303B-371318-254-04 Pogo Pin, 04 Pin, 2.54P, 10u'', 5.0H 1.3 Stroke, SMT

INQURY 303B-371318-254-02

303B-371318-254-02 Pogo Pin, 02 Pin, 2.54P, 10u'', 5.0H 1.3 Stroke, SMT

INQURY 303B-C4418-254-XX

303B-C4418-254-XX Machine Pin, 2.54P, 10u", H4.4x1.8, Cap, SMT

INQURY 303B-411806-254-XX

303B-411806-254-XX Pogo Pin, Right Angle, XX Pin, 2.54P, 10u'', 2.5H, Cap, DIP

INQURY 303B-443118-254-XX

303B-443118-254-XX Pogo Pin, XX Pin, 2.54P, 10u'', 7.5H 3.1 Stroke, Cap, SMT

INQURY 303B-351819-25-000

303B-351819-25-000 Pogo Pin, R/A, 2P Pitch 2.5mm T/L 5.3mm W/H 3.9mm

INQURY 303D-L236M040

303D-L236M040 Pogo Pin Magnetic, 4P H5.0 3.0mm, DIP, 10u", IP67

INQURY 303D-L236F040

303D-L236F040 Machine Pin Magnetic, 4P H4.5 3.0mm, DIP, 10u", IP67

INQURY 303D-L186M020

303D-L186M020 Pogo Pin Magnetic, 2P H5.0 4.0mm, DIP, 10u", IP67

INQURY 303D-L186F020

303D-L186F020 Machine Pin Magnetic, 2P H4.5 4.0mm, DIP, 10u", IP67

INQURY 303C-281220-40-02

303C-281220-40-02 Pogo Pin Magnetic, 2P H5.3, Pitch 4.0mm, 10u", White

INQURY 303C-C4315-40-02

303C-C4315-40-02 Machine Pin Magnetic, 2P H4.3, 4.0mm, DIP, 5u", White

INQURY 303D-L280M04

303D-L280M04 Pogo Pin Magnetic, 4P 28.0x4.8x6h, 5u", 500g, 2A

INQURY 303D-L380F04

303D-L380F04 Machine Pin Magnetic, 4P 38.0x5.3x8.5h, 5u", 500g, 5A

INQURY 303D-L255M03

303D-L255M03 Pogo Pin Magnetic, 3P 25.5x4.8x6h, 5u", 500g, 2A

INQURY 303D-L355F03

303D-L355F03 Machine Pin Magnetic, 3P 35.5x5.3x8.5h, 5u", 500g, 3A

INQURY 303D-D080M02

303D-D080M02 Pogo Pin Magnetic, 2P 8.0D, DIP, 10u", 200g, 2A

INQURY 303D-D080F02

303D-D080F02 Machine Pin Magnetic, 2P 8.0D, DIP, 10u", 200g, 5A

INQURY 303D-D100F02

303D-D100F02 Machine Pin Magnetic, 2P 10.0D, DIP, 10u", 500g, 5A

INQURY 303C-321018-30-04

303C-321018-30-04 Pogo Pin Magnetic, 4P H4.6, Pitch 3.0mm, DIP, 5u", Black

INQURY 303C-C4115-30-04

303C-C4115-30-04